LiFePO4 battery (Expert guide on lithium iron

Jun 4, 2021 · Lithium Iron Phosphate (LiFePO4) batteries continue to dominate the battery storage arena in 2025 thanks to their high energy density, compact

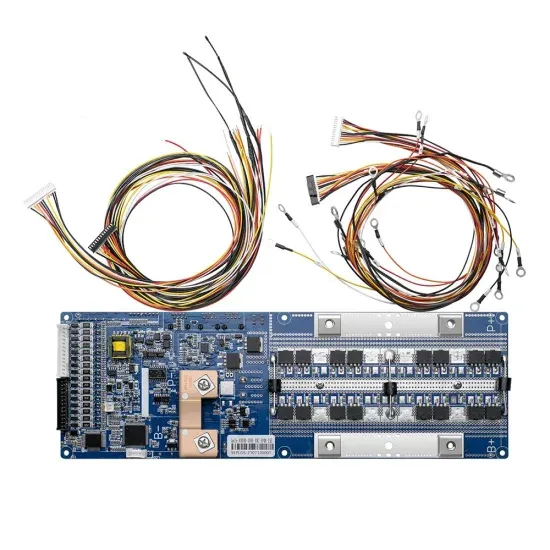

Battery Management System LifePO4

Jan 10, 2024 · Choosing a LifePO4 Battery Management System (BMS) is an excellent decision for maintaining the safety, efficiency, and longevity of your lithium iron phosphate batteries.

BMS 12/200 for 12,8 Volt Lithium-Iron-Phosphate Batteries

Jan 12, 2016 · Why lithium-iron-phosphate? Lithium-iron-phosphate (LiFePO4 or LFP) is the safest of the mainstream li-ion battery types. The nominal voltage of a LFP cell is 3,2V (lead

Smart BMS for lithium iron phosphate battery: Unlocking

Jul 26, 2025 · In the context of Smart BMS for lithium iron phosphate battery, this article examines the development, key benefits, technical application, and commercial significance of smart

Are Lithium Iron Phosphate (LiFePO4) Batteries

Dec 20, 2022 · Learn about the safety features and potential risks of lithium iron phosphate (LiFePO4) batteries. They have a lower risk of overheating and

BATTERY MANAGEMENT SYSTEM DESIGN BMS FOR LITHIUM ION BATTERIES

Do lithium iron phosphate (LiFePO4) batteries need to be balanced? To ensure proper charging, always use a charger specifically designed for the voltage of the battery. By using the correct

Why BMS (Battery Management System) Is So Important In LiFePO4 Batteries?

Apr 14, 2021 · All Lithtech lifepo4 batteries come along with a BMS integrated inside or outside. Let''s have a closer look at how Lithtech BMS optimizes the life of a lithium iron phosphate

Optimum Selection of Lithium Iron Phosphate Battery Cells

Mar 20, 2025 · This paper presents a systematic approach to selecting lithium iron phosphate (LFP) battery cells for electric vehicle (EV) applications, considering cost, volume, aging

BMS — The Important Part of Lifepo4 Battery

Jan 24, 2020 · BMS — The Important Part of Lifepo4 Battery Lithium iron phosphate (LiFePO4) batteries come in a single package with a lot of power and value. This chemistry of lithium

LITHIUM BATTERY MANAGEMENT SYSTEMS BMS

Lithium Iron Phosphate (LiFePO4) batteries offer an outstanding balance of safety, performance, and longevity. However, their full potential can only be realized by adhering to the proper

Design of Battery Management System (BMS) for Lithium Iron Phosphate

Nov 21, 2019 · Lithium iron phosphate battery (LFP) is one of the longest lifetime lithium ion batteries. However, its application in the long-term needs requires specific con

Design of Battery Management System (BMS) for

Jun 21, 2024 · Design of Battery Management System (BMS) for Lithium Iron Phosphate (LFP) Battery Muhammad Nizam Department of Electrical Engineering Universitas Sebelas Maret

Lithium Series, Parallel and Series and Parallel

Mar 23, 2021 · Lithium Series, Parallel and Series and Parallel Connections Introduction Lithium battery banks using batteries with built-in Battery Management Systems (BMS) are created by

Choosing the Right BMS for Your Lithium Iron Phosphate Battery

Oct 14, 2024 · In this article, we will discuss the key factors to consider when selecting a BMS for your LiFePO4 battery, and how to make the best choice for your specific needs. A BMS is a

Bastel BMS Battery Management Test System Features

The LiFePO4 (Lithium Iron Phosphate) battery has gained immense popularity for its longevity, safety, and reliability, making it a top choice for applications like RVs, solar energy systems,

6 FAQs about [Bastel lithium iron phosphate bms battery]

How do I choose a BMS for a LiFePO4 battery?

Compatibility: Ensure that the BMS is specifically designed for LiFePO4 cells. Different battery chemistries require different BMS configurations, so it's crucial to select a BMS compatible with LiFePO4 chemistry. Voltage and Current Monitoring: The BMS should accurately monitor the voltage and current of each cell in the LiFePO4 battery pack.

What is the best BMS for lithium & LiFePO4 batteries?

Choosing the best BMS for lithium and LiFePO4 batteries can be a challenge if you are not familiar with all the terms and with so many brands on the market that all claim to be the best. JK BMS, JBD Smart BMS, and DALY BMS are the best BMS makers out there, but this article reveals that there are levels to that, too.

What is a battery management system (BMS)?

Battery management systems (BMS) are essential components that ensure the safe and efficient operation of battery packs. They are responsible for monitoring and managing various battery parameters, including voltage, current, temperature, and state of charge.

What is the function of BMS in a battery pack?

The essential fun ction of BMS was cell protection. It protects or flame, wh ich decreases batt ery life . BMS ensures that the battery works according to its specification limits. working conditi ons of the batteries . In a battery pack, identical voltages.

Can a BMS synchronize a lithium ion battery?

The simulation results indicate that the designed BMS can precisely synchronize the SOC while minimizing the output voltage ripple. Diagnosing the state-of-health of lithium ion batteries in-operando is becoming increasingly important for multiple applications.

What are LiFePO4 BMS units?

LiFePO4 BMS units are optimized for the specific characteristics of lithium iron phosphate cells, such as their lower nominal voltage, stable discharge profile, and superior thermal stability. This enables simpler charge and discharge management while avoiding issues like lithium plating.

Update Information

- Dushanbe lithium iron phosphate bms battery

- Sarajevo lithium iron phosphate battery bms wholesale

- Czech Brno lithium iron phosphate energy storage battery

- Lithium iron phosphate battery pack press assembly

- Assembly 24V lithium iron phosphate battery pack

- Three-phase energy storage lithium iron phosphate battery

- Energy storage lithium iron phosphate secondary battery

- Production of lithium iron phosphate battery pack

- Vientiane lithium iron phosphate energy storage battery cabinet

- Rechargeable lithium iron phosphate battery pack

- Lithium iron phosphate battery pack product introduction

- 4 strings of 12v50a lithium iron phosphate battery pack

- Lithium iron phosphate battery assembly 12 volt outdoor power supply

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.