Energy Storage System PCB: Design, Challenges,

Jun 14, 2025 · At the heart of these systems lies the Printed Circuit Board (PCB), which ensures efficient power conversion, battery management, and system

Energy storage lithium battery pcb circuit board

The BMS board can be used for lithium-ion battery management purposes. You need to learn about the information on the BMS board before you choose one. A BMS board is a physical

New Energy PCB | New Energy PCB Original In China

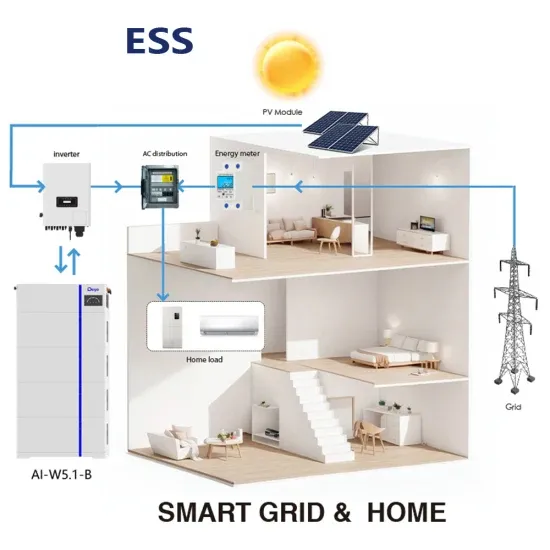

What is a New Energy PCB? A New Energy PCB (Printed Circuit Board) is a specialized circuit board designed to meet the unique requirements of new energy applications, including

What Is Battery PCBA? Everything Beginners Need to Know

Jul 3, 2025 · In the age of portable power, battery-driven devices—from smartphones and electric scooters to solar storage systems—are becoming increasingly sophisticated. One of the core

Energy Storage PCB Circuit Board Manufacturers: What You

But when it comes to energy storage PCB circuit board manufacturers, the stakes are higher than your average TikTok scroll session. We''re talking grid-scale battery farms, electric vehicle

Energy Harvesting PCB Layout and Manufacturing Essentials

Energy harvesting pcb (Printed Circuit Board) is a circuit board applied in energy storage devices (e.g. batteries, supercapacitors) to manage, protect and control the charging and discharging

How much does the energy storage pcb cost

The 2020 Cost and Performance Assessment provided installed costs for six energy storage technologies: lithium-ion (Li-ion) batteries, lead-acid batteries, vanadium redox flow batteries,

What Is a BMS PCB Board? A Beginner''s Guide to Battery

Jun 3, 2025 · A BMS PCB board (Battery Management System Printed Circuit Board) is a specialized circuit board designed to monitor and protect battery packs. It acts as the "brain" of

What is Battery PCB board

Jul 17, 2024 · In practical applications, Battery circuit board are widely used in smartphones, tablets, laptops, wearable devices, and various portable electronic products. These devices

Energy Storage PCB Assembly Manufacturer | Inverter PCB

In the fast-growing field of energy storage, the reliability of every circuit board is vital. A single PCB failure can lead to battery system malfunction, reduced energy efficiency, costly

Energy Storage PCB Function: The Brain Behind Modern

At the end of the day, understanding energy storage PCB functions isn''t just for engineers anymore. Whether you''re a homeowner comparing solar batteries or a facilities manager

What are the Characteristics of Energy Storage PCB

Apr 11, 2024 · 3. Similarly, due to the operation of high current, the board is more likely to have heating problems, so the energy storage PCB board will do heat dissipation treatment, such as

Botswana Energy Storage PCB: Innovations Powering a

Let''s face it – energy storage isn''t exactly the topic that gets people buzzing at dinner parties. But in Botswana, where solar irradiance averages 3,200 hours annually, the humble Printed Circuit

The Critical Role of PCB Boards in Energy Storage Inverters:

Chaos, right? That''s exactly what happens when a energy storage inverter PCB board fails in renewable energy systems. As the backbone of modern energy storage solutions, these

Discussing the key factors in energy storage PCB design and

Jul 22, 2025 · With the sharp rise in market demand, the importance of energy storage PCB (Printed Circuit Board) has become increasingly prominent. Energy storage PCB plays a vital

Lithium Battery Protection Board (PCB) and Battery

Jul 11, 2025 · Lithium batteries play a vital role in modern electric vehicles (EVs), energy storage systems (ESS), and portable devices. To ensure the safety, efficiency, and longevity of lithium

Solutions for energy storage

Aug 16, 2025 · Industrial storage Energy storage devices have long been used in commercial buildings and factories to provide uninterruptible power supply. New technologies extend the

PCB and Energy Storage: The Hidden Connection Powering

Jun 30, 2024 · Why Your Energy Storage System is Secretly a PCB Party Ever wondered what makes modern energy storage systems tick? The real MVP might be smaller than your

Characteristic of Energy Storage PCB

Oct 31, 2023 · 3. Similarly, due to the operation of high current, the board is more likely to have heating problems, so the energy storage PCB board will do heat dissipation treatment, such as

Battery PCB Board: Design, Functionality, and Applications

Dec 17, 2024 · A Battery PCB Board (or Battery Management PCB) is a specialized circuit board designed to control and manage rechargeable or non-rechargeable battery systems. It

PCB and Energy Storage: The Hidden Connection Powering

Jun 30, 2024 · Ever wondered what makes modern energy storage systems tick? The real MVP might be smaller than your smartphone - we''re talking about printed circuit boards (PCBs).

Do Energy Storage Batteries Have PCB Boards Key

May 12, 2025 · Summary: This article explores the critical role of PCB boards in energy storage batteries, analyzing their design principles, industry applications, and emerging trends.

6 FAQs about [Does the energy storage battery have a PCB board ]

What does a battery do on a PCB?

People use this little device to power their everyday objects; remotes, flashlights, toys, chargers, and more. On a PCB, a battery basically stores chemical energy and converts it into usable electronic energy to power the different circuits present on the board.

What is the difference between PCB and battery PCB?

PCB is a physical board that provides a platform for connecting and supporting electronic components in a circuit. Battery PCB refers to a specific printed circuit board designed for battery applications, focusing on protection and monitoring functions.

What is a battery charger PCB board?

A battery charger PCB board is new and high quality. It adopts pure copper wire thickened pcb, which can be used at the same time and has a long service life. It can be used to charge a battery or the original battery. Integrated micro USB interface is also a feature of the battery charger PCB board.

What is battery PCB & BMS PCB?

Battery PCB refers to a specific printed circuit board designed for battery applications, focusing on protection and monitoring functions. The BMS PCB, as part of the BMS, is the specific PCB responsible for housing the electronic components and circuits related to battery management.

What is BMS PCB board for lithium batteries?

Advanced Battery Protection: The BMS PCB Board for Lithium Batteries integrates advanced protective circuitry designed to prevent issues such as overcharging, over-discharging, and short-circuiting. This feature guarantees the battery’s long-term well-being and safeguards its safety.

What is a BMS PCB board used for?

3. Common Applications of BMS PCB Boards BMS PCB boards are used in a wide range of products and industries: Electric Vehicles (EVs and e-Bikes): Ensures safe charging/discharging of high-voltage lithium packs. Renewable Energy Storage: Monitors and balances batteries in solar or wind power systems.

Update Information

- Is there a PCB in the energy storage battery

- Huawei Energy Storage Battery

- Male energy storage battery sales manufacturer

- Sodium battery energy storage project

- Ghana energy storage battery model

- Pretoria s new generation battery energy storage system

- Communication base station energy storage battery solar factory direct sales

- Battery Energy Storage in Spain

- Czech Brno lithium iron phosphate energy storage battery

- Battery Energy Storage System Project in New York USA

- Home energy storage battery company

- Port Vila Industrial Energy Storage Battery Cabinet Photovoltaic

- Latvian lithium-ion energy storage battery brand

Solar Storage Container Market Growth

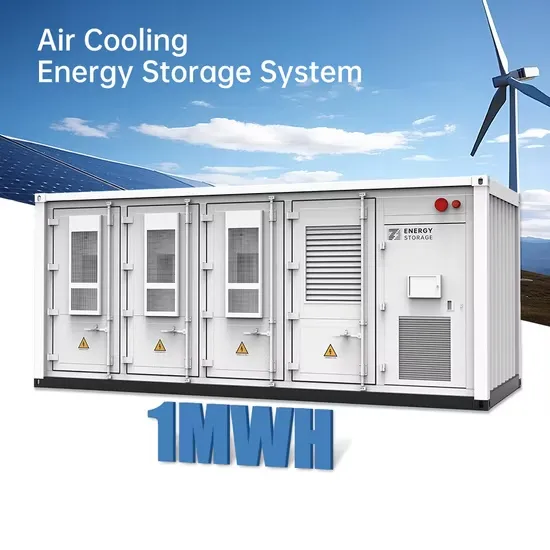

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.