Microsoft Word

Dec 11, 2020 · Lead-Acid Batteries Capital Cost While lead-acid battery technology is considered mature, recent industry R&D has focused on improving the performance required for grid-scale

How Does Lead-Acid Battery Cost and Longevity Relate?

Mar 5, 2025 · The cost and longevity of a lead-acid battery are directly related—higher-quality batteries tend to last longer, reducing long-term costs despite their higher initial price. Lead

What Is the True Cost Difference Between Lead-Acid and

Mar 20, 2025 · Short Answer: Lithium rack batteries have higher upfront costs but lower long-term expenses due to longer lifespan, minimal maintenance, and better efficiency. Lead-acid

Evaluating the Cost of Flooded Lead Acid Batteries vs

Apr 11, 2025 · Flooded lead acid batteries offer lower upfront costs ($100-$300) but higher long-term expenses due to maintenance and shorter lifespans. Lithium-ion alternatives cost 3-5x

A comparative life cycle assessment of lithium-ion and lead-acid

Jul 15, 2022 · The nickel cobalt aluminum battery is the best performer for climate change and resource use (fossil fuels) among the analysed lithium-ion batteries, with 45% less impact. The

The True Cost of Lithium vs. Lead-Acid Batteries in Material

Feb 17, 2025 · The Verdict: Lithium Delivers Long-Term Savings While lead-acid batteries seem more affordable upfront, their ongoing costs in maintenance, downtime, and replacements

What''s the Proper Way to Connect NOCO Genius 10 to a Car Battery?

3 days ago · AGM batteries take longer to reach full charge than standard lead-acid types – sometimes up to 12 hours for deeply discharged units. Can I use the NOCO Genius 10 on a

The Cost to Replace Lead Acid Batteries: A Comprehensive

Feb 14, 2025 · Different types of lead-acid batteries vary significantly in price: Starter lead-acid batteries (SLI) (such as car batteries): $50-$200. Deep cycle lead-acid batteries (such as

Evaluating the Cost of Flooded Lead Acid Batteries vs

Apr 11, 2025 · Flooded lead acid batteries typically cost $100-$300 per kWh, making them the cheapest upfront option. Industrial models range up to $5,000 for 2,000Ah capacity.

How much does energy storage lead-acid battery cost

Apr 12, 2024 · Generally, the price for lead-acid batteries per kilowatt-hour (kWh) of storage can range from $100 to $200, but costs may rise depending on the aforementioned variables. For

Lithium vs. Lead-Acid Batteries: A Comprehensive 10-Year Cost

Apr 11, 2025 · Lithium-ion batteries offer superior long-term value, with a 10-year net cost of $9,300 compared to lead-acid''s $16,400. Beyond cost savings, lithium systems deliver

Lead-Acid Battery : Components, Reactions & Charging

The lead-acid accumulator remains one of the most widely used rechargeable batteries due to its cost-effectiveness, reliability, and high surge current capability. Although newer battery

Technology: Lead-Acid Battery

Sep 15, 2024 · System Design There are two general types of lead-acid batteries: closed and sealed designs. In closed lead-acid batteries, the electrolyte consists of water-diluted sulphuric

What Is Lead Acid Battery Capacity?

Nov 13, 2024 · A lead acid battery is an electrochemical power source which produces voltage through a chemical reaction between two unlike plates immersed in the electrolyte (a solution

A Guide To Lead-Acid Batteries

Dec 5, 2020 · Structure and Operation Most lead-acid batteries are constructed with the positive electrode (the anode) made from a lead-antimony alloy with lead (IV) oxide pressed into it,

Best 12v 7ah Battery [Updated On: August 2025]

Aug 19, 2025 · ExpertPower YTX7A-BS 12v7ah lead_acid_battery – Best for Motorcycle and Powersport Use ML7-12 Mighty Max 12V 7.2Ah SLA Battery – Best Value 12v 7ah Battery

Thermal-electrochemical simulation of lead-acid battery

Dec 15, 2021 · Finally, the obtained results show that the presented ROM can both accurately simulate the lead-acid battery and reduce the computational cost (speed-up factor of 17) which

Lead Acid Battery: Definition, Types, Charging

Nov 23, 2024 · The lead-acid battery, invented by Gaston Planté in 1859, is the first rechargeable battery. It generates energy through chemical reactions

Size and Weight of 20Ah Batteries: Lead-Acid vs. Lithium-Ion

Apr 20, 2025 · When considering batteries for various applications, understanding the size and weight differences between 20Ah lead-acid and lithium-ion batteries is crucial. A typical 20Ah

LiFePo4 vs Lead Acid Batteries: 7 Key Attributes

Jan 28, 2024 · Key Takeaways LiFePO4 batteries have higher energy density than lead acid batteries. They also have a longer lifespan. Lead acid batteries

Lithium vs Lead-Acid Battery: Comprehensive

May 9, 2025 · Compare Lithium vs Lead-Acid battery: lifespan, cost, performance, weight, maintenance & efficiency. Explore pros/cons, ideal applications (home,

Lithium vs. Lead-Acid Batteries: A Dollar per kWh per Year Cost

Jan 3, 2025 · Here''s why many people think lead-acid batteries are a better deal: You get ~20 kWh of capacity for around $5,000 with typical deep-cycle marine-grade or AGM lead-acid

What is a Lead-Acid Battery?

Feb 20, 2025 · A lead-acid battery is a type of rechargeable battery that uses lead plates and sulfuric acid to store and release electrical energy. First invented in 1859 by French engineer

6 FAQs about [What is the approximate cost of a lead-acid battery BMS]

Are lead-acid batteries a better deal?

Here’s why many people think lead-acid batteries are a better deal: You get ~20 kWh of capacity for around $5,000 with typical deep-cycle marine-grade or AGM lead-acid batteries, but say, only ~10 kWh for around $4,000 with high-quality lithium ones. But we must look beyond the nominal dollar per kWh. All batteries die.

How much does a marine battery cost?

You get ~20 kWh of capacity for around $5,000 with typical deep-cycle marine-grade or AGM lead-acid batteries, but say, only ~10 kWh for around $4,000 with high-quality lithium ones. But we must look beyond the nominal dollar per kWh. All batteries die. The longer you can use them, the less you pay over their lifetime.

Are lithium batteries more expensive than lead-acid batteries for off-grid solar solutions?

Many think lithium batteries are more expensive than lead-acid ones for off-grid solar solutions. But is that really true? We use lithium batteries in all our solutions because of their performance, longevity, and lower cost. So let’s do the math to see why this chemistry is the most cost-effective.

How much does a battery management system BMS cost?

You can expect to pay between 1.6 to 200 for each Battery Management System Bms. The cost of a Battery Management System Bms varies by the different parameters. Meet China Battery Management System Bms manufacturers, wholesalers, exporters featured in the Consumer Electronics industry from China.

How much does a 10 kWh AGM battery cost?

While a 10 kWh AGM’s energy cost is $ 0.57/kWh, 3.5 times more! Using the same method, the energy cost of Lithium Ion batteries (such as Tesla, LG Chem, Panasonic) is around $ 0.30/kWh. If you have any questions or need any further information, please email us at [email protected] or Call us at (877) 497 6937.

How much does a battery bank cost per year?

Let’s combine all the factors and calculate the cost per kWh per year to see which option offers a better deal. A client paid ~$5,000 for a ~19.2 kWh battery bank. Let’s be generous and round it up to 20 kWh for easy calculation.

Update Information

- What are the functions of battery BMS

- High quality lithium battery bms cost

- What does BMS mean in battery

- ADI lead-acid battery bms

- Main functions of Mongolia BMS battery management system

- What is vanadium liquid flow battery

- Kigali BMS Battery Management Power System Enterprise

- Lithium battery pack active balancing BMS passive balancing

- What is the normal temperature of the tool battery

- Battery double-layer BMS system

- What are the battery cabinet communication power supply technologies

- What type of battery is the energy storage cabinet battery called

- Specific functions of power battery BMS

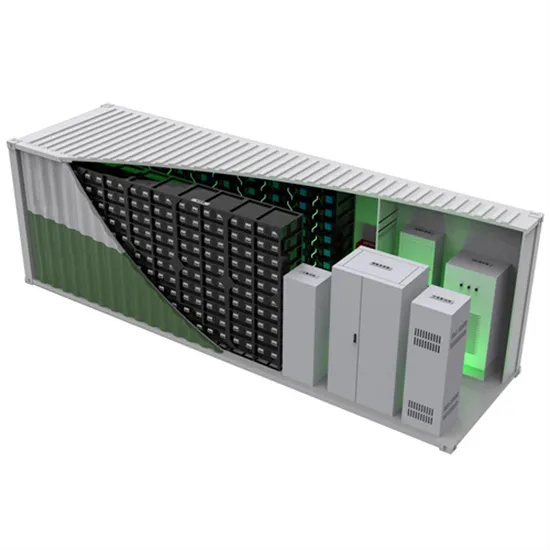

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.