What is double-sided double-glass solar energy

Oct 6, 2024 · The term "double-sided double-glass solar energy" encapsulates a method of solar energy collection that employs two layers of glass to enhance

The Difference Between Double-glass and Single

Aug 17, 2023 · The main difference between double-glass photovoltaic modules and single-sided glass solar panels lies in their construction and design, which

What does it mean when a mirror is double sided?

Jul 7, 2022 · When people look into a mirror, they see an image of themselves behind the glass. The mirror does not reverse the image left to right; it reverses it front to back. For example,

Understanding the Double-Sided Nature of Jiggers: A

Feb 10, 2025 · A Brief History of Jiggers Before we dive into the specifics of double-sided jiggers, it''s helpful to understand their history. The jigger has evolved significantly since its inception,

Polaris solar photovoltaic double glass components will

Analysis forecast, double glass components share will be 2020 by 2019 20% share of growth to 30%, the heat storage device and showed a trend of increasing year by year, is expected to

What is a double-sided double-glass photovoltaic module?

Jul 7, 2022 · Functional level: longer life cycle PERC double-glass double-sided modules integrate the anti-PID characteristics of double-glass modules, and have the advantages of high

Journey Through the History of Double Glazing Windows

Contrary to popular belief, double glazing did not initially originate in the realm of glass or windows. It was actually devised by Charles D Haven, a refrigerator engineer, to address the

Defects in double-sided incremental forming of woven fabric

Aug 1, 2025 · In double-sided incremental forming of woven prepregs, the multi-layer layup, i.e. dummy sheets positioned above and below the prepreg layer, poses challenges for the in-situ

How Double-Sided Polishing Can Revolutionize Optical

Aug 17, 2025 · Precision Glass & Optics integrated a PR Hoffman double-sided polisher (DSP) into the production lineup. Transformed ability to manufacture optical components.

Effects of polishing parameters on surface quality in sapphire double

Jun 15, 2020 · Abstract To reveal the influence of polishing process parameters on the surface quality of sapphire after double-sided chemical mechanical polishing (CMP), the orthogonal

6 FAQs about [When did the double-sided double-glass components appear ]

How did double glazing come to be?

Let’s dive into the history/evolution of double glazing to understand how this popular window instalment came to be. The history/evolution of double glazing dates back to the 1870s, when it was first conceptualized and used in homes.

Why was double glazing important in the 1970s?

The 1970s marked a turning point for double glazing as awareness of energy conservation and environmental concerns grew. Governments and industries worldwide began to focus on developing more sustainable building practices. Double-glazed windows and doors became an important part of this movement.

When did double glazing take off?

During the 1980s, double glazing certainly took off. Huge numbers of homes started to benefit from its insulating qualities for both windows and doors. Those of us ‘of a certain age’ will remember a windswept Ted Moult, the celebrity Derbyshire farmer who was the reassuring presence on our screens, extolling the virtues of draught-free windows.

Are double glazed windows a modern phenomenon?

However, the double glazing windows with gaps filled with some gases and sealed shut is a modern phenomenon. Double glazed windows are also called storm windows and they are in practice for a long time.

Why did LOF Glass make double glazed windows?

Inspired by Charles D Haven’s double pane design for the refrigerator, the LOF Glass company partnered with the engineer to build double glazed windows. They launched these windows in 1938, however it failed due to the sealant failures.

When did double glazed doors become popular?

In the 1860s, a Scottish scientist named Thomas Young developed the idea of trapping air between two panes of glass to enhance thermal insulation. It wasn't until the 1930s that double glazing started gaining popularity. During this time, double glazed doors and double glazed windows began to be used in commercial buildings and high-end homes.

Update Information

- Hungary s cheap monocrystalline double-glass components

- Double-sided double-glass photovoltaic panel manufacturers

- Double-sided double-glass component parameters

- Photovoltaic double-glass components to build a sun room

- Inverter power components

- 110kw inverter with 275 components

- Basic components of wind and solar complementary communication base stations

- What are the components of the base station power supply system

- Photovoltaic development components energy storage inverter

- All-vanadium redox flow battery components

- Main components of portable energy storage

- High crystal components and single crystal double glass

- What are the components of an energy storage power station

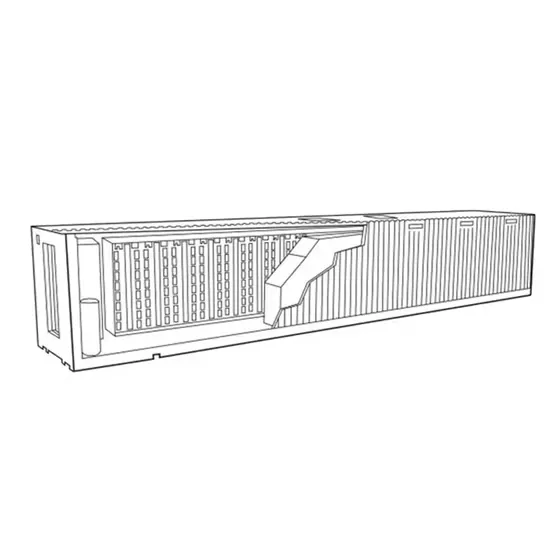

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

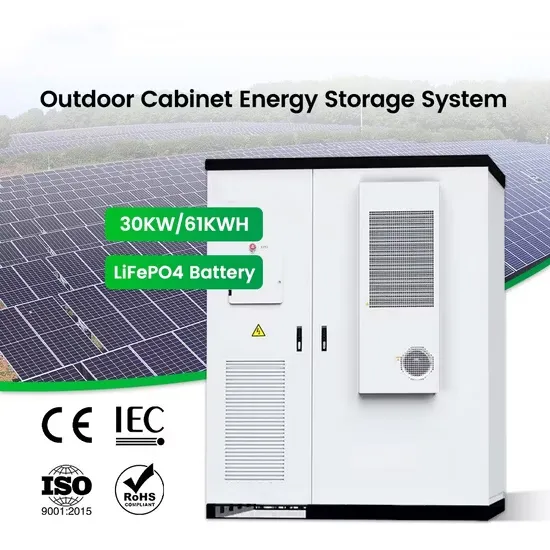

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.