How does a cabinet battery work?

Jun 30, 2025 · As a seasoned cabinet battery supplier, I''ve witnessed the growing curiosity around how these essential power storage units operate. Cabinet batteries are pivotal in

Case Study– Battery Cabinet Application: Energy

Mar 31, 2023 · This article describes Eabel''s custom battery cabinet designed for the lithium-ion battery industry. It highlights the cabinet''s features, safety

Battery Cabinet Tech: Core Processes & Edge

With the transformation of energy structure and the increasing demand for intelligent power system, Energy Storage Battery cabinets have become important infrastructure in industrial

Battery Energy Storage Cabinet Construction Process: From

Phase 1: Design - Where Engineers Play 4D Chess Think of this stage as planning a spaceship that needs to survive both Arctic winters and desert summers. The design process for battery

Product and Process Data Structure for Automated Battery

Feb 14, 2025 · Generalized process flow diagram according to IDEF0 with all basic inputs, controls, mechanisms and outputs (ICOMs) that are required to carry out an automated battery

Battery cabinets are process materials

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process, from

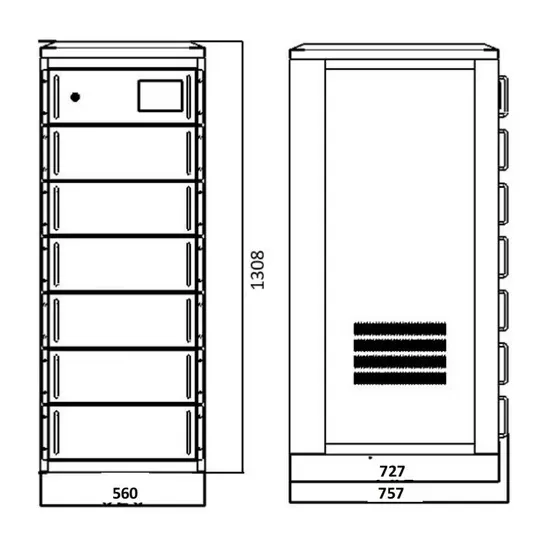

Structural diagram of large energy storage battery cabinet

typical structure of the Battery Energy Storage System (BESS) is illustrated in Figure 2, which mainly includes battery cells, Battery Management System (BMS), Power Conversion System...

Energy storage high voltage cabinet structure

age Systems are structured in two main parts. The power conversion system (PCS) handles AC/DC and DC/AC conversion, with energy flowing into the batteries to charge them or being

Battery Cabinet Ventilation Design | HuiJue Group E-Site

Feb 27, 2023 · Why Thermal Management Could Make or Break Energy Storage Systems? As lithium-ion batteries dominate energy storage, battery cabinet ventilation design has emerged

LITHIUM BATTERY CABINET STRUCTURE DESIGN

Structure of lithium battery storage cabinet The structural design of the new lithium battery energy storage cabinet involves many aspects such as Shell, battery module, BMS, thermal

Battery Cabinet Cost Structure and Optimiza-tion

Jan 12, 2024 · The main method for gathering data about the cost structures was to interview the subcontractor and people involved in the design process of a battery cabinet, e.g. mechanical

Structural composition of energy storage cabinet

The battery energy storage system is installed in a container-type structure, with built-in monitoring system, automatic fire protection system, temperature control system, energy

Structural battery composites with remarkable energy

Feb 15, 2023 · Here, a high performance SBC based on system structural design are demonstrated by directly embedding battery materials into carbon fiber composite via a

How to design an energy storage cabinet: integration and

Jan 3, 2025 · The design of an energy storage cabinet usually follows the following steps: Demand analysis: Determine basic parameters such as energy storage capacity, load

Battery cabinets are process materials

A battery cabinet system is an integrated assembly of batteries enclosed in a protective cabinet, designed for various applications, including peak shaving, backup power, 4 ???· The

Battery cabinet installation construction process

Mounting mechanism - they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box

Battery cabinets are process materials

What are structure-battery materials? A term "structure-battery" materials has been applied to such designs [90,96]. This approach targets elimination of inert mass of the battery enclosure

Energy storage cabinet structure design atlas

In this review, we first introduce recent research developments pertaining to electrodes, electrolytes, separators, and interface engineering, all tailored to structure plus composites for

Structural diagram of large energy storage battery cabinet

Lithium-ion battery energy storage system (BESS) has rapidly developed and widely applied due to its high energy density and high flexibility. However, the frequent occurrence of fire and

6 FAQs about [Battery cabinet system structure design process]

What are the parts of a battery storage cabinet?

Let’s look at the most common parts: Frame – it forms the outer structure. In most cases, you will mount or weld various panels on the structure. The battery storage cabinet may have top, bottom, and side panels. Door – allows you to access the battery box enclosure. You can use hinges to attach the door to the enclosure structure.

How to build a battery cabinet?

Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box. You can choose steel or aluminum material. They form the perfect option for battery cabinet fabrication. Step 3: With the dimension from step 1, cut the sheet metal to appropriate sizes.

How to install a battery storage cabinet?

Mounting mechanism – they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box enclosure appropriately. Racks – these systems support batteries in the enclosure. Ideally, the battery rack should be strong.

How do you choose a battery cabinet?

Again, the door should have a safe locking mechanism or latch. In more advanced battery cabinets, they may have alarm systems. Ventilation systems – they may integrate louvers. Depending on the enclosure design, the ventilation systems can be at the top or bottom section. Ventilation systems also help during the cooling process.

What type of batteries are used in energy storage cabinets?

Lithium batteries have become the most commonly used battery type in modern energy storage cabinets due to their high energy density, long life, low self-discharge rate and fast charge and discharge speed.

What is energy storage cabinet?

Energy Storage Cabinet is a vital part of modern energy management system, especially when storing and dispatching energy between renewable energy (such as solar energy and wind energy) and power grid. As the global demand for clean energy increases, the design and optimization of energy storage sys

Update Information

- New Energy Battery Cabinet Base Station Power Structure

- Production process site of energy storage battery cabinet

- New Energy Battery Cabinet Process

- Battery cabinet factory production process

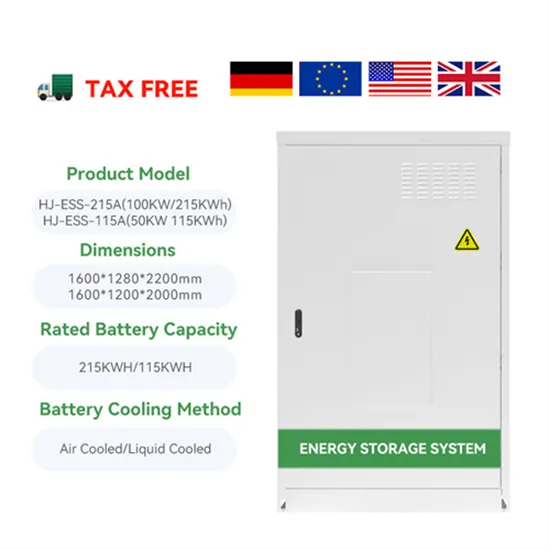

- Energy storage battery cabinet photovoltaic structure

- New Energy New Energy Battery Cabinet Structure

- The process of replacing lithium batteries in Nauru s outdoor communication battery cabinet

- Lithium battery station cabinet design

- Battery cabinet structural design highlights

- Energy Storage Battery Cabinet Design Method

- Battery cabinet base station power module power consumption

- Battery accessories in Huawei energy storage cabinet

- Battery Cabinet Photovoltaic Price

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.