Lithium-ion Battery Manufacturing Process

Dec 14, 2024 · Cathode Material Preparation and Slurry Mixing. 1. Mixing Ratio: According to the battery formulation requirements, accurately weigh the ratio of active material, conductive

Industrial Mixing for Battery and Energy Storage Industries

STORAGE INDUSTRY Resodyn Acoustic Mixers, Inc. supplies its advanced mixing technology to the Energy Storage Industry enabling manufacturers to quickly and efficiently process diverse

Efficient mixing technology for battery production

With IKA''s special mixing solutions, this goal is reliably achieved by means of concentrated energy input and constant product and dispersion quality. Find out in our latest application

The Critical Role of Slurry Mixing in India''s Battery Push

May 17, 2025 · India''s Vision for Battery Manufacturing and the role slurry mixing plays in it India''s commitment to a sustainable future, driven by the growing adoption of electric vehicles and the

Improved Mixing Performance Drives Innovation

Jul 1, 2024 · A key aspect of improving energy storage is high-performing lithium-ion batteries (LiBs), and a key player in the pursuit of battery technology

The Future of Battery Slurry Mixing

Feb 22, 2024 · One of the key objectives of BATMACHINE project is to develop a slurry mixing/dispersion machinery. The goal would be to make it highly efficient for different slurry

Efficient mixing technology for battery production

Lithium-ion batteries are essential for supplying energy to e-cars or mobile electrical appliances. As the demand for these electrical storage systems will continue to rise in the future, their

Battery production

5 days ago · Battery performance and lifetime constitute a bottleneck for electric vehicles as well as stationary electric energy storage systems to penetrate the market. One thing is already

Revolutionary continuous mixing process for producing Li

Jan 26, 2018 · Bühler has used continuous mixing for many decades in various industries and for diverse applications. The company''s process engineers developed the continuous mixing

Dry Electrode Manufacturing in a Calender: The

May 5, 2023 · The dry manufacturing of battery electrodes has the potential to significantly reduce costs and the environmental impact of battery production

Mixing methods for solid state electrodes: Techniques,

May 15, 2023 · They demonstrate the viability of melt granulation by a high-shear mixer equipped with heaters to melt the binder, as a dry mixing method and its coupling in a process chain to

Revolutionizing Energy Storage: the Advancements in Battery Mixing

Oct 16, 2024 · Battery mixing equipment plays a crucial role in the manufacturing process of lithium-ion batteries, which are widely used in various applications, including electric vehicles,

Effects of dry powder mixing on electrochemical

Oct 15, 2023 · This research examines how the morphology of the electrode powder mixture affects the structure and battery performance of lithium-ion battery electrodes fabricated using

A review of research in the Li-ion battery production and

Sep 15, 2023 · Through measuring the data directly from HOBO UX 120-006M data loggers and Onset CTV-A current meters of Johnson Controls'' pilot-scale manufacturing facility, [78] found

Preparation Technologies for Lithium-Ion Batteries

Mar 5, 2021 · The EIRICH mixer with its unique working prin- ciple offers fantastic possibilities along the entire process chain, from the production of raw materials and the preparation of

An Effective Mixing for Lithium Ion Battery Slurries

Jan 1, 2014 · A thorough mixing of these slurries poses a major challenge in the battery manufacturing process. Several types of mixing devices and mixing

Advanced lithium-ion battery process manufacturing

Jul 18, 2025 · Large-scale electrode preparation in battery cell manufacturing plants starts with pregrinding and premixing, two essential steps for higher yields in the downstream mixing and

Processing and Manufacturing of Electrodes for Lithium-Ion Batteries

Aug 6, 2024 · 5. Hawley, W.B. and J. Li, Beneficial rheological properties of lithium-ion battery cathode slurries from elevated mixing and coating temperatures. Journal of Energy Storage,

From Materials to Cell: State-of-the-Art and

Oct 27, 2021 · Electrode processing plays an important role in advancing lithium-ion battery technologies and has a significant impact on cell energy density,

Particle interactions during dry powder mixing and their

Apr 1, 2024 · As solvent-free battery manufacturing evolves from the quest for low energy consumption, the understanding of interactions and behavior of battery materials and their

Challenges and Opportunities with Continuous Electrode

Jun 24, 2025 · Cur-rently, the slurry mixing process takes place in a batch mixer, most commonly a planetary mixer. In the result, the opportunities and disadvantages of transitioning to a

Masterdokument_Zellherstellung_v63 Vordruckfreigabe

The battery production department focuses on battery production technology. Member companies supply machines, plants, machine components, tools and services in the entire process chain

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

EV Battery Manufacturing Process

Mar 19, 2022 · With the rise of e-mobility, including electric cars and energy storage systems, it''s critical to build more affordable and long-lasting batteries. The following is the EV

Advances in Material Processing for Energy Storage

Jul 16, 2024 · New materials and formulations for cathodes, anodes and electrolytic compounds are constantly under development to improve energy densities, increase batery or storage life,

Exploring the mixing process of lithium-ion

Apr 21, 2025 · Lithium-ion battery mixing equipment plays a vital role in lithium battery production. Its working principle involves many complex and delicate

6 FAQs about [Energy storage battery mixing process]

How to choose the Right Battery slurry mixing equipment?

Selecting the right mixing equipment is a paramount decision in electrode manufacturing and the battery slurry mixing process. It ensures efficient integration of materials, maintaining the mixture’s quality and consistency. Understanding the unique needs of battery slurry applications guides the equipment selection.

How to prepare a battery slurry?

Cathode Material Preparation and Slurry Mixing 1. Mixing Ratio: According to the battery formulation requirements, accurately weigh the ratio of active material, conductive agent, and binder. This ratio is usually optimized to balance the battery’s capacity, cycle life, and safety performance. 2.

Why is monitoring important in battery slurry mixing?

Consistent monitoring of key process parameters is critical to achieving optimal battery slurry mixing outcomes. Precise tracking of factors such as temperature, viscosity, and pH levels enables operators to proactively adjust the mixing process to ensure uniform dispersion and stability.

Why is temperature control important in battery slurry mixing?

Embrace “smart” and “adaptive” technologies that transform the art of continuous mixing into a streamlined science. Careful temperature control in battery slurry mixing is a linchpin of process optimization, as precise thermal regulation prevents undesirable reactions. It ensures both homogeneity and longevity of the slurry.

How does slurry mixing affect battery performance?

Slurry mixing strongly affects the final performance of the battery. Mixing techniques are divided depending on the use (wet) or not (dry) of a solvent. The choice of the mixing conditions must be studied according to the desired outcome.

How does electrode preparation affect battery performance?

In this regard, the first step of the electrode preparation, which consists mostly of mixing all the electrode components to obtain small particles homogeneously dispersed in the slurry, strongly affects the final performance of the battery.

Update Information

- Production process site of energy storage battery cabinet

- Malta lithium battery energy storage company

- Ghana energy storage battery model

- Communication base station energy storage battery solar factory direct sales

- Battery Energy Storage System Project in New York USA

- Kinshasa Industrial and Commercial Energy Storage Battery Merchants

- Which energy storage battery is better in Djibouti

- Lithium battery station cabinet base station energy and process

- Lithium battery energy storage container transportation

- Huawei Malaysia Energy Storage Battery

- The size of PCS power affects the energy storage battery

- Main types of battery energy storage systems

- Grenada EK43 degree energy storage battery cabinet

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

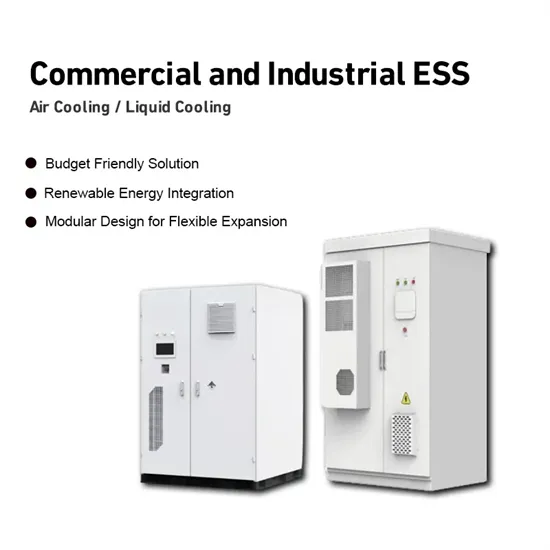

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.