IBMU Battery Monitoring Unit

Dec 5, 2019 · Monitors the real-time data of cell internal resistance and temperature which will detect battery capacity changes in time & avoid thermal runaway risks. Locate the faulty

Optimal configuration of 5G base station energy storage

Mar 17, 2022 · Abstract: The high-energy consumption and high construction density of 5G base stations have greatly increased the demand for backup energy storage batteries. To maximize

Cooling for Mobile Base Stations and Cell Towers

BackgroundUnattended base stations require an intelligent cooling system because of the strain they are exposed to. The sensitive telecom equipment is operating 24/7 with continuous load

Changing batteries in base station | SimpliSafe Support Home

Aug 16, 2020 · Changing batteries in base station Is there a manual, with photos or step by step instructions, showing how to replace the battery in the base station? I had a power outage and

Comprehensive BTS Monitoring Solution

Jul 30, 2021 · Introduction Base stations are key elements in any mobile network. Their monitoring and upgrade functions are essential for operators to compete with other multiservice providers.

Battery Health Monitoring Unit | Efftronics Systems Pvt Ltd

A Battery Health Monitoring System (BHMS) is a highly advanced and intelligent system which is used to monitor battery health and its efficiency remotly. A BHMS ensures complete safety and

CELLGUARD™ Wireless | Franklin Grid Solutions

Comprised of a Base Coordinator Unit (BCU) and single-battery sensor modules, the system provides both visual and digital battery state-of-health and is capable of monitoring up to 16

Cooling for Mobile Base Stations and Cell Towers

May 5, 2025 · Remote monitoring and control of the cooling system is vital to ensure the working condition of the machines distributed in different base stations. When the power to a cellular

Battery monitors & balancers | TI

Aug 19, 2025 · For battery management systems in HEV/EV, our automotive battery monitors and balancers integrate noise filtering to eliminate the need for external components. For industrial

TELECOM SITES POWER CONTROL & MANAGEMENT

Feb 16, 2024 · Introduction Power issues are the most fundamental item that network operators need to monitor and manage at remote sites. The ability to remotely monitor and reboot

6 FAQs about [Base station battery monitoring unit]

Why do telecom base stations need a battery management system?

As the backbone of modern communications, telecom base stations demand a highly reliable and efficient power backup system. The application of Battery Management Systems in telecom backup batteries is a game-changing innovation that enhances safety, extends battery lifespan, improves operational efficiency, and ensures regulatory compliance.

How does a battery monitoring system work?

The BMS monitors each battery cell individually and: Prevents Overcharging: By continuously tracking the battery voltage and state of charge, the BMS stops the charging process once optimal levels are reached. This prevents excessive heat buildup and potential fire hazards.

How many sensors does a battery monitoring system have?

Comprised of a Base Coordinator Unit (BCU) and single-battery sensor modules, the system provides both visual and digital battery state-of-health and is capable of monitoring up to 16 battery strings, up to 300 sensors per string, and up to 600 sensors per BCU (irrespective of how they are divided by strings).

What is a battery management system (BMS)?

A BMS equalizes the charge among cells, enhancing overall performance and longevity. Protection: The system prevents overcharging, deep discharging, overheating, and short circuits. By triggering alarms or disconnecting problematic cells, a BMS minimizes the risk of battery failure and hazardous incidents.

What is Conductance-based battery monitoring?

Conductance-based monitoring technology provides the most accurate, efficient, and non-invasive method possible for monitoring a battery’s state-of-health.

Why do telecom base stations need backup batteries?

Backup batteries ensure that telecom base stations remain operational even during extended power outages. With increasing demand for reliable data connectivity and the critical nature of emergency communications, maintaining battery health is essential.

Update Information

- Communication base station inverter battery detection unit

- 5g base station electromagnetic battery monitoring

- Tehran lithium battery station cabinet base station

- Liquid flow battery for 5G communication base station in Windhoek

- Mobile outdoor directional base station battery

- Base station lead-acid battery ESS power base station

- Base station battery pack test system

- 2 Carrier frequency 800m digital trunking communication base station battery energy storage system

- Base station lead-acid battery base station power generation method

- Sierra Leone 5g base station battery power supply

- Battery cabinet and distribution cabinet installation ESS power base station

- Does the communication base station flow battery have a battery

- How much does it cost to build a communication base station lead-acid battery

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

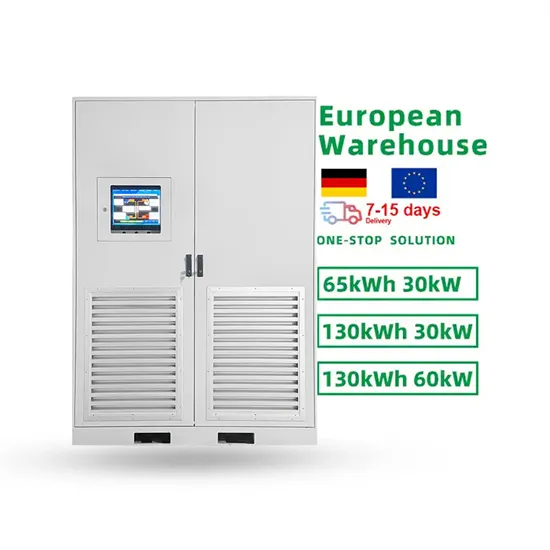

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.