Pouch Cell vs Tabless Cell Batteries – Tool Tech Talk

Feb 9, 2024 · Pouch Cell vs Tabless Cylindrical Cell Batteries What is a Pouch Cell Battery? Pouch cells have been in the power tool industry longer than tabless cylindrical cells. We first

Circular Battery vs Cylindrical Battery: Find the Right Fit

Feb 20, 2025 · Circular and cylindrical batteries differ in characteristics and applications. This article helps you choose the right one for optimal performance.

Which application scenarios are suitable for

Jul 15, 2025 · The high energy density and long lifespan of cylindrical lithium batteries make electric tools lighter and more convenient to work with, while

[LiFePO4 Battery Types] Cylindrical vs. Prismatic

Oct 22, 2024 · LiFePO4 batteries, or lithium iron phosphate batteries, are increasingly recognized for their remarkable safety, longevity, and versatility.

Which application scenarios are suitable for

Jul 15, 2025 · The widespread application of cylindrical lithium batteries is due to their advantages of high energy density, long lifespan, good safety, and high

Cylindrical Cell Assembly Machines: The Precision

Feb 7, 2025 · In the rapidly evolving world of battery technology, the cylindrical cell assembly machine stands out as a linchpin of modern manufacturing. Designed to automate the

Key Applications of Cylindrical Lithium Batteries Explained

Jun 18, 2025 · Cylindrical lithium batteries are also popular in the power tool industry. Their lightweight and compact design make them perfect for battery-operated tools used in

What Are the Key Applications of Cylindrical Battery Cells in

Feb 21, 2025 · In renewable energy systems, cylindrical batteries store energy generated from solar or wind sources. Their durability and efficiency make them suitable for large-scale energy

How to Choose a Cylindrical Lithium Battery

Dec 17, 2024 · Cylindrical lithium batteries are widely used in various applications due to their high energy density, long cycle life, and excellent safety features. These batteries are

How to Choose the Best Cylindrical Cell Battery for Your Needs

Dec 15, 2024 · To choose the right cylindrical cell battery, consider factors such as voltage requirements, capacity (Ah), size compatibility, and discharge rates. Assess your specific

The advantages of cylinder battery vs square

Aug 17, 2025 · Tesla is using cylindrical cells in their electric vehicles over square cells because cylindrical cells prove more reliable from cylinder battery vs

Exploring Assembly and Testing of Cylindrical

Nov 15, 2024 · Known for their reliability, efficiency, and versatility, cylindrical batteries have become a critical component in grid-scale battery energy

Applications of Cylindrical Lithium Batteries in Power Tools

Cylindrical lithium batteries have become the cornerstone of modern power tools, revolutionizing the way these devices operate and enhancing their overall performance. In the realm of power

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · In this study, we design a loading apparatus capable of precisely measuring the relationship between the loading distance and the contact area between the battery and the

[SDI Focus] Cylindrical Batteries Evolve Into 46-phi batteries

Jan 7, 2025 · Cylindrical batteries have been a part of lithium-ion battery''s history since its commercialization. Long favored by the market, cylindrical batteries, which have been evolved

Transformation and Competition in the Global Cylindrical Battery

Apr 21, 2025 · The global cylindrical battery market is undergoing a structural transformation, primarily driven by advancements in technology and improvements in manufacturing

How to Understand Cylindrical Cell Batteries

Dec 17, 2024 · Cylindrical cell batteries are a popular choice in various industries due to their high energy density, durability, and versatility. These batteries are commonly used in portable

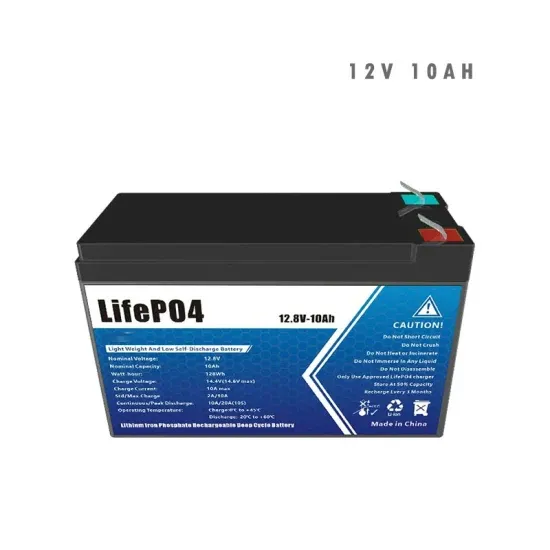

LiFePO4 Cylindrical Cells: Why Are They The Best Choice For Power Tools?

Nov 4, 2024 · What Are LiFePO4 Cylindrical Cells? LiFePO4 cylindrical cells are the best choice for power tools because they offer several advantages over other types of batteries. For one,

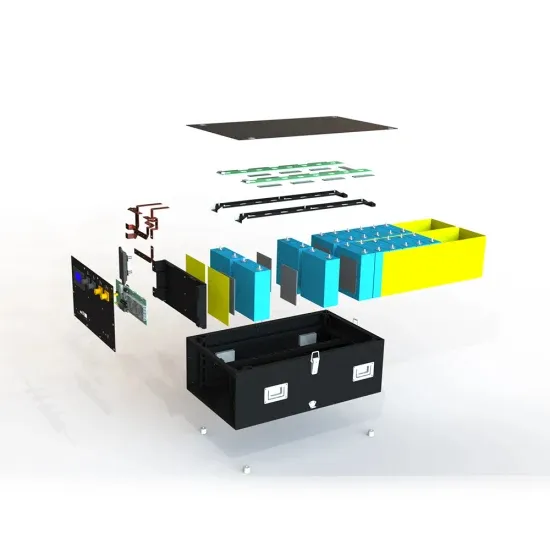

How Cylindrical Battery Cells Are Made

Jun 20, 2025 · You''ve probably seen cylindrical batteries everywhere - from your TV remote to power tools. But what sets them apart from other battery types? The magic lies in their unique

Why Are Batteries Designed in a Cylinder Shape? An In

Feb 21, 2025 · Batteries are predominantly designed in a cylindrical shape due to several structural, manufacturing, and performance-related advantages. This design choice enhances

What Are the Key Applications of Cylindrical Battery Cells in

Feb 21, 2025 · Cylindrical battery cells, known for their robust design and efficiency, play a critical role across numerous industries. These cells are widely used in consumer electronics, electric

6 FAQs about [Using cylindrical batteries as tool batteries]

What is a cylindrical battery?

Known for their reliability, efficiency, and versatility, cylindrical batteries have become a critical component in grid-scale battery energy storage systems (BESS). What sets these cells apart from other battery types is their rigid cylindrical structure, which enables efficient packing and cooling.

What is a cylindrical lithium battery used for?

Cylindrical lithium batteries can be used as power sources. In addition, they can also be seen in digital cameras, MP3 players, notebook computers, car starters, power tools, and other portable electronic products. Part 2. Structure of cylindrical battery

How many cells does a power tool battery use?

When you make a power tool battery, you still need to use multiple cells just like you do with round cells. 18V/20V max batteries use 5-cell sets, 12V batteries use 3-cell sets, 36V batteries use 10-cell sets, and the list goes on. As Flex and DeWalt’s naming suggests, you stack these cells on top of one another when you build the pack.

What are cylindrical battery cells used for?

With a robust design and well-established manufacturing principles, cylindrical battery cells are widely used in high-energy-density applications ranging from electric vehicles (EVs) to laptops and other portable devices.

What makes a cylindrical battery a good fit?

This makes them a good fit for applications such as EVs, as the high energy density facilitates a longer range between charges. The cylindrical battery assembly process starts with validating incoming cells to ensure they meet required manufacturing specifications through inspections and tests.

Why is a cylindrical lithium battery a bad battery?

The cylindrical lithium battery cell size is larger. When the current is discharged, the internal temperature of the winding core is relatively high. The activity at the edge of the cylindrical lithium battery pole piece is poor. Battery performance declines more obviously after long-term use.

Update Information

- Cylindrical lithium batteries have direction

- Managua s first mass production of cylindrical lithium batteries

- How many types of cylindrical lithium batteries are there

- Balancing of cylindrical lithium batteries

- Common models of cylindrical lithium batteries

- What are the small cylindrical lithium batteries

- How many brands of tool batteries are there in Krakow Poland

- Are all tool lithium batteries universal

- What are the types of small cylindrical lithium batteries

- Energy storage power plant using new energy vehicle batteries

- The prospects of lead-carbon energy storage batteries

- Stacking Energy Storage Batteries

- How many types of Duodoma energy storage batteries are there

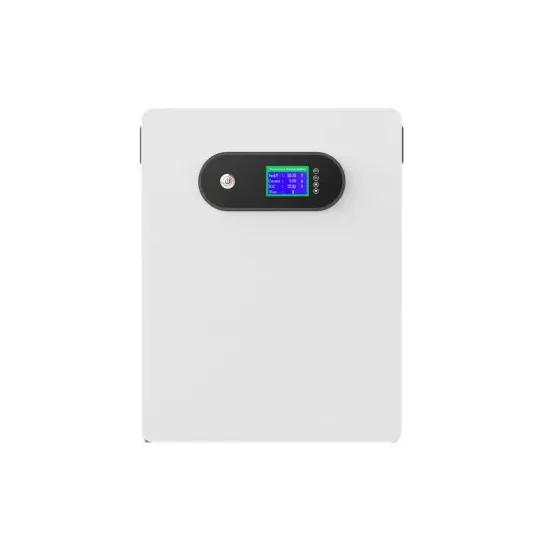

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.