Manufacture of Advanced Battery Metal Containers

May 13, 2013 · HTTM is currently in production on five new battery container programs with two new customers (US & Europe). Staffing has included addition of 9 new FT employees + 19 FTE.

Plastic Battery Container Manufacturing Plant Setup Cost

23 hours ago · List of machinery needed for Plastic battery container manufacturing plant production Estimated costs and suppliers Raw Material Costs Types of materials required and

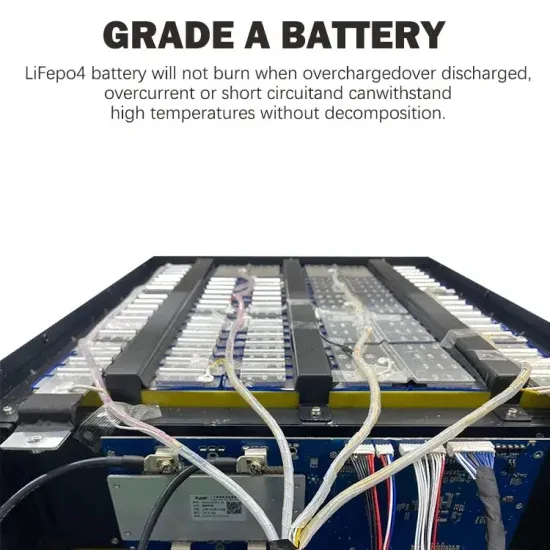

TWS ESS Battery Solutions-2023-0223

Jun 21, 2023 · Dynamic Leadership in Innovative Rechargeable Lithium-ion Battery Solutions TWS, a dynamic and global industry leader focused on providing innovative Lithium-based

Battery Pack Assembly Process Series 7

Jun 6, 2025 · The manufacturing quality of energy storage containers highly relies on precise and reliable equipment support - whether it is the production consistency of battery units, the

Plastic Battery Containers Manufacturing Business.

Mar 19, 2025 · The report titled "Market Survey cum Detailed Techno Economic Feasibility Report on Plastic Battery Containers." provides an insight into Plastic Battery Containers market in

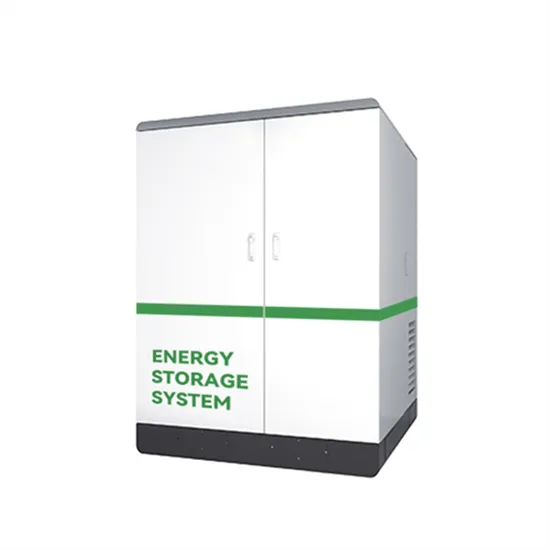

Battery Storage Containers – Future of Sustainable Energy

Jun 20, 2025 · Battery storage containers are pre-engineered container units equipped with high-capacity batteries, often lithium-ion, and energy management systems. These containers are

Plastic Battery Containers Manufacturing Business.

Mar 19, 2025 · Introduction Automobile battery containers are used to carry the Batteries. A battery container made of molded plastic and preferably formed in a single unitary structure.

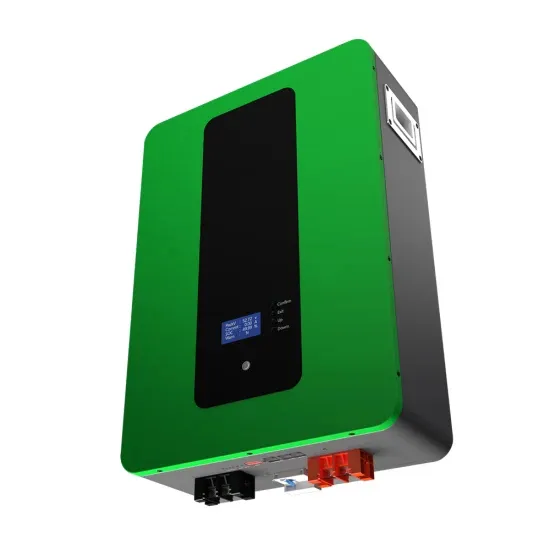

Container Industrial and Commercial Energy Storage System

Boost your energy independence with our Container Industrial and Commercial Energy Storage System—a powerful 100kWh-215kWh solution with hybrid inverter, MPPT, and full safety

The Essential Guide to Battery Containers in China

Jan 23, 2025 · Understanding the intricacies of battery container design, manufacturing, and regulations is crucial for industry stakeholders. This guide aims to provide a comprehensive

Rolls-Royce expands battery container production

Aug 19, 2020 · The Rolls-Royce''s business unit Power Systems is increasing its capacities for producing battery containers. From 2021 the MTU EnergyPacks are to be manufactured in the

BATTERY CONTAINER DESIGN SIMULATION AND

Aug 20, 2024 · The Digital Engineering wing recommended a 712-ton machine as the optimal choice for container production. Moreover, the Toolworks design process now integrates

Rolls-Royce expands battery container production

Aug 19, 2020 · PRESS RELEASE Power Generation Rolls-Royce expands battery container production Posted on August 19, 2020 The Rolls-Royce''s business unit Power Systems is

Global Mass Production and Delivery in June: CORNEX

May 21, 2025 · Under its 1500V platform, the 20-foot CORNEX M6 battery energy storage container—equipped with 472Ah cells—delivers 6.28MWh capacity, supporting 2+ hour

PRODUCTION OF LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The Chair of Production Engineering of E-Mobility Components (PEM) of RWTH Aachen University has been researching lithium-ion battery production for many years. The

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · The Battery Production specialist department is the point of contact for all questions relating to battery machinery and plant engineering. It researches technology and market

Battery Container Guide: Safe & Sustainable | Wi

Aug 13, 2025 · Battery containers from Wi-Sales meet the highest safety standards and are UN-certified to minimize risks during transport and storage.

电池储能系统集装箱| BESS

4 days ago · 电池储能系统集装箱| 贝斯 价格下降刺激需求,商业和工业储能系统(社会科学与应用科学学院)现在流行起来了!2023年以来,碳酸锂、硅材料

Wärtsilä swappable battery containers enabling

Jul 9, 2021 · The technology group Wärtsilä has developed and delivered a mobile battery container solution that will enable inland waterway vessels to

Smart containers in battery production

Jan 1, 2024 · Battery production mainly takes place in clean and dry rooms and therefore under controlled conditions. Between the production steps, transportation is required, which also

Development of Containerized Energy Storage System

Dec 24, 2014 · We have developed our Energy Storage System (ESS) using lithium-ion batteries, and we have already conducted verification testing of the system installed in a container, and

6 FAQs about [Battery container production]

What is a battery container?

UNISEG's Battery Container is designed for the safe and convenient storage and transportation of waste / used lead acid batteries (car & automotive).

What makes a battery container sustainable?

Sustainability is the focus of the battery container industry. The use of recyclable materials and the promotion of the circular economy are central pillars. Recyclable materials: Use of recyclable components. Durability: designed for multiple use and long life cycles.

Why are battery containers important?

The industry relies on innovative, adaptable and sustainable solutions to meet the requirements of modern energy storage. By taking environmental aspects into account, developing customized solutions and integrating new technologies, battery containers are making an important contribution to the energy transition and mobility of the future.

What makes a battery container a good choice?

Special features such as fire-resistant materials and absorption elements minimize risks such as overheating or leaks. Sustainability is the focus of the battery container industry. The use of recyclable materials and the promotion of the circular economy are central pillars.

How do battery containers work?

The Battery Containers are initially deployed at customer sites (used battery generators), by the Battery Collector / SMD. When full the Battery Collector will deliver an empty exchange BTS Container simultaneously picking up the full Container.

What are the requirements for battery containers?

The requirements for battery containers vary greatly depending on the area of application and battery type. Specific dimensions: Adaptation to individual size requirements. Material selection: Selection of materials based on application requirements. Protection functions: Integration of security features according to the risk assessment.

Update Information

- Roman energy storage container production

- Albania communication base station battery production

- Lithium iron phosphate battery container

- Home battery finished container base station

- Battery cabinet production line base station

- Battery cabinet factory production process

- Gabon container nickel-cadmium battery

- How much does a storage battery container cost for a base station

- Battery cabinet production in Podgorica with quality assurance

- One megawatt energy storage battery container

- Battery container for energy storage power station in Argentina

- Somalia container battery factory energy

- Energy storage container production design factory operation

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.