How to calculate the heating power of the battery cabinet

Part 4. Battery run time calculation examples Here are case studies demonstrating how to calculate battery run time for various devices and scenarios: Example 1: Power Tool Battery

Calculation of the number of batteries in the fire

The three main battery types are alkaline batteries, lithium batteries, and rechargeable batteries (such as nickel-metal hydride or lithium-ion). How often do you need to replace an alarm

Study on performance effects for battery energy storage

Feb 1, 2025 · This study uses the battery volumetric heat generation rate equation and battery total heat calculation formula proposed by Bernardi et al., and can effectively calculate the

How to calculate the battery cabinet occupied by single

Learn about how to calculate the battery size for applications like Uninterrupted Power Supply (UPS), solar PV system, telecommunications, and other auxiliary services in power system

Battery cabinet liquid cooling and heating power

Calculate the sum of all the heat required to heat up the battery pack components and the heat dissipated by the box to obtain the total heat of heating. Then according to the specific

Battery cost calculation formula for battery swap cabinet

A decision model is developed for battery valuation in battery swapping station. The model achieves the tradeoff of battery use between energy and transportation. Battery for both

Battery loss calculation of battery swap cabinet

Idle batteries in the battery swap stations (BSSs) of electric vehicles (EVs) can be used as regulated power sources. Considering the battery swap service and the frequency regulation

Battery storage cabinet: how to determine its required

Jun 20, 2025 · So, calculate how much capacity is required for a Battery Storage Cabinet? How should it be calculated? First of all, the key lies in clarifying "how much electricity you need to

How is the rated energy of the energy storage cabinet

Aug 4, 2024 · Battery capacity is a critical determinant of rated energy in an energy storage cabinet. It is measured in ampere-hours (Ah) and essentially indicates the total amount of

Battery cabinet cooling power calculation formula

Power Substation Design Calculations – A Checklist of 18 Why conduct auxiliary power transformer calculations? Not all loads in the station rely on DC power. The HVAC system,

Battery cabinet heating power calculation

Three-phase UPS battery cabinets 1085HR battery cabinets – welded The 1085 model cabinets can support Eaton, CSB, Enersys, North-star, and Yuasa batteries from 280 watts/cell up to

How to calculate the battery power of the energy

The battery energy calculator allows you to calculate the battery energy of a single cell or a battery pack. You need to enter the battery cell capacity, voltage, number of cells and choose

Thermal Simulation and Analysis of Outdoor Energy Storage Battery

Jan 8, 2024 · Maintaining low and uniform temperature distribution, and low energy consumption of the battery storage is very important. We studied the fluid dynamics and heat transfer

Understanding Energy Calculations for Containerized Battery Energy

Jun 17, 2025 · 👉 Want to estimate how much energy your containerized battery system can deliver? Let''s break it down step by step. 🔍 Start with the basics — know your cell. To calculate

Numerical calculation of temperature field of energy storage battery

Numerical calculation of temperature field of energy storage battery module and optimization design of heat dissipation system [J]. Energy Storage Science and Technology, 2024, 13 (4):

Battery cabinet liquid cooling and heating power calculation

Battery cabinet liquid cooling and heating power calculation (PDF) A Review of Advanced Cooling Strategies for Research studies on phase change material cooling and direct liquid cooling for

Battery cabinet cooling power calculation

Selection and calculation method of telecom cabinet air The calculation of the heat released by the components in the cabinet is based on the following (related to the components

Simulation analysis and optimization of containerized energy

Sep 10, 2024 · The air-cooling system is of great significance in the battery thermal management system because of its simple structure and low cost. This study analyses the thermal

electricity calculation of industrial and commercial energy

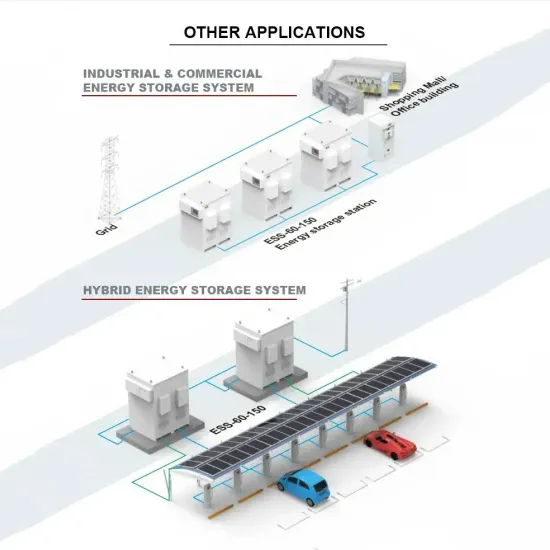

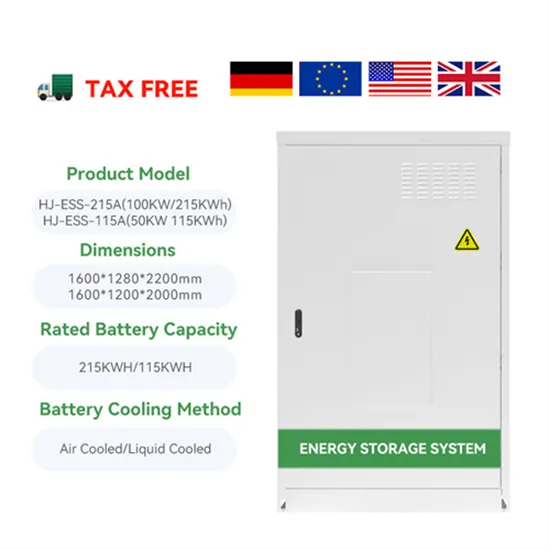

Commercial and industrial energy storage system cabinets Adopting the design concept of "ALL in one", it integrates long-life battery cells, battery management system (BMS), high-performance

Calculation of heat generation of energy storage battery cabinet

Battery pack calculator : Capacity, C-rating, ampere, charge and discharge run-time calculator of a battery or pack of batteries (energy storage) Calculation of battery pack capacity, c-rate, run

Battery cabinet liquid cooling and heating power

What is liquid coolant-based battery thermal management? Liquid coolant-based BTMS is the most commonly utilized scheme considering its high heat transfer efficiency in cooling or

Mastering Physical Battery Energy Storage Calculation: A

Jun 20, 2022 · Physical battery energy storage calculation isn''t just spreadsheet work; it''s the backbone of efficient power systems. This guide speaks directly to engineers, project

Ventilation and Breathing of Battery Rooms

Mar 30, 2006 · Maintenance-free or "closed" batteries are installed in some UPS systems. batteries can be neither topped up with water nor maintained. The charging of a battery

Energy storage cabinet battery power weight calculation

Energy storage cabinet battery power weight calculation sources without new energy storage resources. 2. There is no rule-of-thumb for how much battery storage is needed to integrate

Energy storage cabinet battery power weight calculation

Battery energy storage (BESS) offer highly efficient and cost-effective energy storage solutions. BESS can be used to balance the electric grid, provide backup power and improve grid

What factors affect the measurement accuracy of battery

What factors affect the measurement accuracy of battery capacity distribution cabinets? - EST group is a national high-tech enterprise that provides full industry supply chain services for the

Calculation method of energy storage cabinet

Conduct an analysis of the customer''s current energy costs based on customer electricity bills. Depending on the purpose of the battery energy storage system, include a description of how

ENERGY STORAGE CABINET COST CALCULATION FORMULA

The battery energy calculator allows you to calculate the battery energy of a single cell or a battery pack. You need to enter the battery cell capacity, voltage, number of cells and choose

Energy efficiency evaluation of a stationary lithium-ion battery

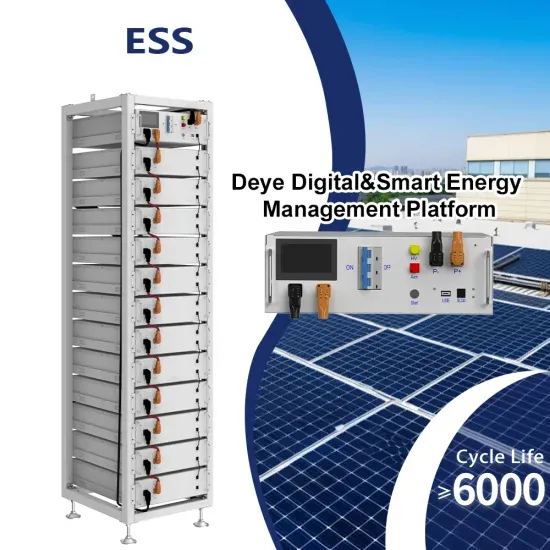

Jan 15, 2018 · Energy efficiency is a key performance indicator for battery storage systems. A detailed electro-thermal model of a stationary lithium-ion battery system is developed and an

6 FAQs about [Energy calculation of battery cabinet]

What type of batteries are used in energy storage cabinets?

Lithium batteries have become the most commonly used battery type in modern energy storage cabinets due to their high energy density, long life, low self-discharge rate and fast charge and discharge speed.

What is energy storage cabinet?

Energy Storage Cabinet is a vital part of modern energy management system, especially when storing and dispatching energy between renewable energy (such as solar energy and wind energy) and power grid. As the global demand for clean energy increases, the design and optimization of energy storage sys

How is energy loss calculated in an isothermal battery calorimeter?

For validation of energy loss calculation, full cycle tests at different current rates are conducted on a single cell placed in an isothermal battery calorimeter at 30 °C. Thus, energy losses can be calculated both from electrical measurement at the cell as well as from cell heat rate to ambient.

How do you calculate energy losses from electrical measurements?

Energy losses from electrical measurements are calculated from the difference between charged and discharged energy of one cycle. Electrical energy is calculated from time integral of the cell current and four-pole measurement of the cell voltage.

What is a typical energy storage system size?

System sizes range from small (under 20 kWh of nominal energy), for residential storage systems which store excess electricity from photovoltaic systems, and medium (under 1 MWh), for local grid applications , to large (over 1 MWh), which are often used for grid ancillary services , .

What is the average efficiency of a battery system?

Values varied from 60% to 75% for the overall system efficiency. Rydh et al. , described a method for the calculation of conversion and overall efficiency of battery systems by including the effect of the air conditioning system, different battery temperatures, and inverter losses.

Update Information

- New Energy Battery Cabinet Heat Conductivity

- UPS battery cabinet voltage calculation

- Charging of liquid-cooled energy storage battery cabinet

- Site Energy Battery Cabinet Free Agent

- Moroni energy storage cabinet battery manufacturer

- Sao Tome and Principe Outdoor Communication Battery Cabinet New Energy

- New energy battery cabinet into the home

- China-Europe Battery Energy Storage Cabinet Manufacturer

- Kampala Outdoor Communication Battery Cabinet Company Energy

- How much does a battery energy storage cabinet cost in Beijing

- Solomon Islands Site Energy Battery Cabinet Factory

- Repair of new energy battery cabinet in Port Louis

- Is the Bloemfontein new energy battery cabinet under warranty

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.