Battery Cabinet

Feb 28, 2025 · Install the Battery Cabinet following local building requirements and applicable codes. Plan the location of the Battery Cabinet site ahead of time, taking into consideration the

EATON 93PM INSTALLATION MANUAL Pdf Download

Page 59: Figure 26. 93Pm Integrated Battery Cabinet Battery String Detail Schematic Onelines and Schematics Figure 26. 93PM Integrated Battery Cabinet Battery String Detail Schematic

Mitsubishi Electric Power Products, Inc. BC43 Battery

Feb 3, 2025 · Battery cabinets that are not supplied with an incorporated DC output disconnect device must have an appropriate disconnect device provided external to the cabinet.

Eaton Samsung Gen 3 Battery Cabinet Installation and

Mar 25, 2025 · Contact your local Authorities Having Jurisdiction (AHJ), to discuss the planned lithium battery installation, including cabinet placement and spacing, as well as total quantities

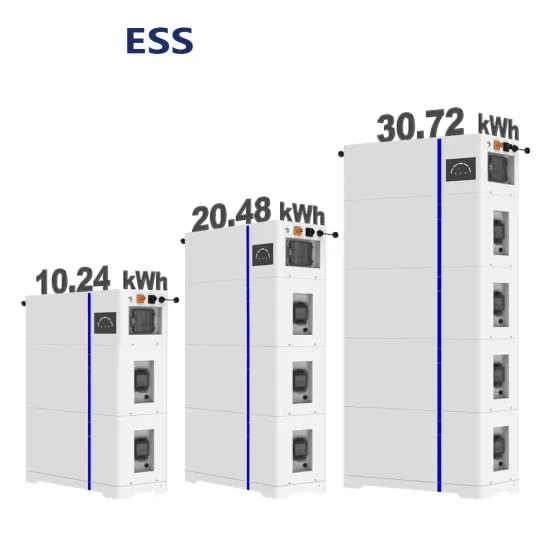

European Household Energy Storage and Anti-Dumping:

Why Europe''s Energy Storage Boom Faces a Regulatory Hurdle European households now install enough battery storage every 3 hours to power a mid-sized village for a day. But behind

Microsoft Word

Nov 15, 2017 · The battery cabinet is equipped with narrow pallet jack or forklift access openings in the front and rear of the cabinet. Move the equipment into the desired location and set in place.

Powerware 9390 Integrated Battery Cabinet (Models IBC

May 2, 2022 · During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load. The

Eaton 93PM Integrated Battery Cabinet-Large and Large

Mar 31, 2025 · Use the following basic sequence of steps to install the Eaton 93PM Integrated Battery Cabinet-Large (IBC-L) or Integrated Battery Cabinet-Large High Rate (IBC-LH):

PDU8000 电池开关柜-T 快速指南 (02405583)

Jan 9, 2020 · 本文档主要介绍电池开关柜安装和调试的操作方法。3 Tools / 安装工具 5 Installing a Battery Switch Cabinet / 安装电池开关柜 PDU8000 Battery Switch Cabinet-T Quick Guide 5.1

Eaton 93E External Battery Cabinet installation manual

Sep 23, 2024 · Chapter 1 Introduction The Eaton® External Battery Cabinet (EBC) provides extended emergency short-term backup power for the 93E 20-30 kVA and 40-60 kVA UPS to

Wooden Cabinets and Vanities and Components Thereof

Apr 21, 2020 · Based on affirmative final determinations by the Department of Commerce (Commerce) and the International Trade Commission (ITC), Commerce is issuing an

-48 VDC Battery Cabinet Installation and User Manual

Apr 21, 2022 · VDC battery cabinet can be mounted in a 23" relay rack or mounted to a wall. The battery cabinet contains one (1) 40 A battery disconnect circuit binets may be daisy chained as

6 FAQs about [Battery cabinet anti-dumping installation]

How do I install a battery cabinet?

The installer should be familiar with the installation requirements and techniques to be used in securing the battery cabinet to a relay rack or wall. The battery cabinet is designed to mount on a wall or a standard 23” wide relay rack. Refer to Figure 3 and install the 23” relay rack mounting angles to the battery cabinet.

What is included in the Battery Cabinet Manual?

This manual contains important instructions that should be followed during installation and operation of the battery cabinet. This product is designed for commercial / industrial use only, with UPS systems. It is not intended for use with life support and other designated critical devices.

Do battery cabinet enclosures have a DIN rail?

Many enclosures have DIN rail. Electronic components –modern battery cabinet enclosures have sensors for smoke, shock, humidity, temperature, and moisture. These are safety measures to ensure the environment within the battery cabinet is safe. However, such enclosures are costlier.

What to do if a battery cabinet is damaged?

In case of damage, notify immediately the carrier. The packing container of the battery cabinet protects it from mechanical and environmental damage. Preserve the packaging for later re-use. Refer in each moment to the electrical scheme at section 3.

How to build a battery cabinet?

Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box. You can choose steel or aluminum material. They form the perfect option for battery cabinet fabrication. Step 3: With the dimension from step 1, cut the sheet metal to appropriate sizes.

How to extrude aluminum battery housing?

During aluminum extrusion for battery housing, you will push a billet through a die. Ideally, you can extrude hollow, semi-hollow, and solid battery housing components. Extruding aluminum battery box enclosure involves: Apart from these, you can make battery cabinet parts through forging or casting.

Update Information

- Battery cabinet installation site in computer room

- Battery cabinet and distribution cabinet installation ESS power base station

- The role of battery cabinet installation in base station power system

- 380vups battery cabinet installation

- Energy storage cabinet battery installation location

- Battery cabinet installation base station in weak current room

- Sudan outdoor communication battery cabinet installation manufacturers ranking

- Ups battery cabinet double row installation spacing

- Integrated system for outdoor communication battery cabinet installation in Croatia

- Shared battery cabinet installation ESS power base station

- C32-120 battery cabinet

- Battery cabinet a322

- Is the battery cabinet a distribution cabinet

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.