In situ Synthesis of Gel Polymer Electrolytes for Lithium

Dec 15, 2024 · 1. Introduction Nowadays, lithium (Li-)ion batteries have become one of the most promising energy storage devices due to their high operating voltage, high energy density,

Pack锂电池基础知识

May 7, 2025 · 锂电池 Pack 是将多个锂电池电芯通过串并联的方式组合在一起,并配备相应的电池管理系统(BMS)、结构件等,以满足特定设备或应用场景

Application of biphenyl additive in electrolyte for liquid state

Jan 31, 2017 · In order to investigate the influence of the biphenyl (BH) as a polymerizable electrolyte additive on the properties of Al-plastic film lithium-ion batteries, we examined the

Gel Polymer Electrolytes Based on Polymerizable Lithium

Aug 7, 2019 · Here, a polymerizable lithium salt, lithium (trifluoromethanesulfonyl) (vinylsulfonyl)imide, was synthesized and used to prepare cross-linked gel polymer electrolyte

Lithium polymer battery pack_LN Energy Technology Co., Ltd.

Jun 27, 2024 · Customizable for various types of polymer lithium battery packs. High rate discharge type: The discharge rate can reach 100C, suitable for remote control vehicle

Polymerizable Deep Eutectic Solvent-Based

Jan 17, 2024 · In this study, lithium bis (trifluoromethane)sulfonimide, acrylamide, and succinonitrile were first used to design a polymerizable monomer. Then, it

Lithium Polymer Battery Manufacturer | LiPo Battery Pack

6 days ago · Custom Lithium Polymer Battery Pack Lithium polymer battery has the highest energy density compared with other types of rechargeable battery, and nearly all of the sizes

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Discover how lithium-ion battery packs are made—sorting, welding, assembly, BMS integration, and testing—to deliver reliable power for EVs,

Lithium Iron Phosphate Battery Packs: Powering the Future

Apr 22, 2025 · In the future, LiFePO₄ battery packs are expected to be more closely integrated with smart grid technologies and energy management systems. This integration will enable

Current trends, challenges, and prospects in material

May 1, 2023 · Current trends, challenges, and prospects in material advances for improving the overall safety of lithium-ion battery pack SurajRana, RajanKumar, Rabinder SinghBharj

Gel Polymer Electrolytes Based on Polymerizable Lithium Salt

Abstract Here, a polymerizable lithium salt, lithium (trifluoromethanesulfonyl) (vinylsulfonyl)imide, was synthesized and used to prepare cross-linked gel polymer electrolyte systems with poly

Design strategy towards flame-retardant gel

Jun 10, 2024 · The emergence of lithium metal batteries (LMBs) as a promising technology in energy storage devices is attributed to their high energy density.

Nonflammable and thermally stable gel polymer electrolytes

Aug 25, 2018 · In summary, we have prepared and characterized a PFPE-based gel polymer electrolyte (FGPE) for lithium battery applications. Among various crosslinker candidates for

In Situ Constructing Robust Interface by Deep Eutectic

Oct 28, 2024 · A polymerizable deep eutectic electrolyte with high fluidity is elaborately designed to promote Li+ transport and ameliorate the interface of (PAN)-based composite solid-state

Amazon : Lithium Polymer Battery Packs

Lithium Polymer Battery (Pack of 2) 7.4V 1500mAh 903462 Rechargeable Battery Pack with Wire JST Connector for Speaker and Wireless Device- Confirm Device & Connector Polarity Before

A PET-enhanced PEO-ionic liquid-based gel polymer

Jan 5, 2025 · Therefore, PEO-IL-based GPEs can provide higher safety performance and regulate the lithium ion flux on LMAs, thus suppressing the growth of lithium dendrites during lithium

Lithium Polymer (Li-Poly) Battery Packs

Mar 5, 2024 · The lithium-polymer cell differentiates itself from conventional battery systems in the type of electrolyte used. The original design, dating back to the 1970s, uses a dry solid

A novel design of lithium-polymer pouch battery pack with

Sep 30, 2024 · Our findings reveal that expanded graphite PCMs offers effective thermal performance with observed improvement of 27 %. Therefore, we recommend employing EG26

Polymer binder for lithium battery and method of manufacturing

A unit cell or building block of a lithium-ion battery is typically composed of an anode current collector, an anode or negative electrode layer (containing an anode active material

Are Polymer-Based Electrolytes Ready for High

Jul 14, 2022 · High-voltage lithium polymer cells are considered an attractive technology that could out-perform commercial lithium-ion batteries in terms of

Self-actuating protection mechanisms for safer lithium

Jul 4, 2024 · For example, as a self-actuating overcharge protection mechanism, polymerizable monomer additive can spontaneously cut off the ion transport to shut down the battery reaction

Additives for Functional Electrolytes of Li-Ion

Jan 1, 2015 · The electrolyte is an indispensable element of Li-ion batteries. In normal operation, the electrolyte does not participate in electrochemical

N-Phenylmaleimide as a new polymerizable additive for

Abstract Electrochemical properties and overcharge behavior of N-phenylmaleimide (NPM) as a new polymerizable electrolyte additive for overcharge protection of lithium-ion batteries are

6 FAQs about [Polymerizable lithium battery pack]

Where can I buy lithium ion polymer (LiPo) battery packs?

Do not show again and take me directly to the Cart. Lithium Ion Polymer (LiPo) Battery Packs are available at Mouser Electronics. Mouser offers inventory, pricing, & datasheets for Lithium Ion Polymer (LiPo) Battery Packs.

What can you do with a custom lithium-ion polymer rechargeable battery?

Wearable products, medical monitors, IoT devices, handheld, and new product designs that require very low profile cells and lower cost batteries. Explore energy solutions with custom lithium-ion polymer rechargeable batteries suppliers and manufacturers. Power up wearables with custom battery packs designed for optimal performance.

Why are custom lithium polymer batteries better than conventional lithium ion cells?

The difference in construction over conventional Li-ion cells allows for lower cost, safer operation, and flexible packaging options. The size of lithium polymer cells is a major factor and what makes custom lithium polymer battery packs and battery assemblies the battery of choice for many applications.

What is a Li Polymer Battery Pack?

A Li Polymer Battery Pack is a type of battery commonly found in portable printing equipment, ECG monitoring systems, laptops, flaw detectors, and electric bicycles. It is known for its less failure rate and high energy density. The quality of this battery pack has been verified through stringent quality checking parameters.

What is a lithium polymer battery?

A lithium polymer battery is an energysaving and longlasting option for lipo batteries. It has a long service life and is suitable for all kinds of high capacity lithium batteries and typec batteries. Lithium polymer batteries are available in AliExpress, along with other good deals on rechargeable batteries, consumer electronics, and accessories & parts.

Why do Li polymer batteries need to be packed together?

For instance, a 2P configuration means two cells in parallel, which doubles the battery’s capacity without changing the voltage. The combination of series and parallel configurations in LiPo packs allows for customization to meet specific voltage and capacity needs. Part 5. Why li polymer batteries need to be packed together?

Update Information

- Cambodia Lithium Battery PACK Factory Introduction

- Ukrainian 12v lithium battery pack

- Backup energy storage lithium iron phosphate battery pack

- 18V photovoltaic energy storage cabinet battery lithium battery pack

- Lithium battery pack safety

- 12V 3-channel 4-channel lithium iron phosphate battery pack

- Türkiye pack lithium battery

- Lithium battery pack consists of several cells

- Kwh lithium battery pack

- Argentina electric stacker lithium battery pack

- Sucre 40a lithium battery pack

- Kyrgyzstan custom lithium battery pack

- Which lithium iron phosphate battery pack in Chad decays faster

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

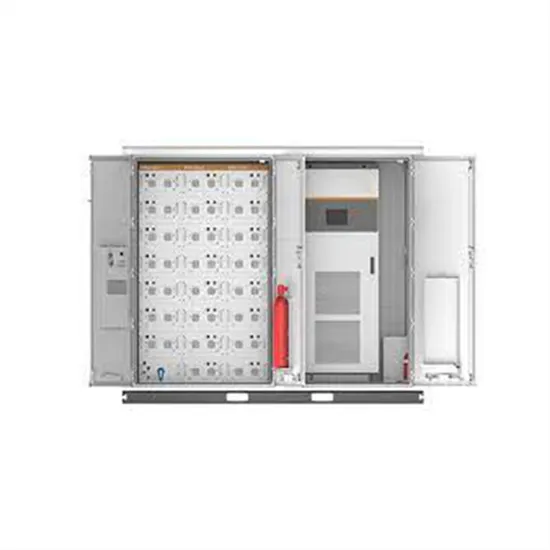

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.