Experimental investigation on the combustion performance of single

Jun 15, 2025 · Under similar glass material conditions, double-glazed modules exhibited superior combustion performance compared to their single-glass counterparts. Therefore, locations

The comparison of single-glass, double-glass and building

Apr 19, 2013 · According to the experimental results 10% of solar radiation has been transmitted through the semi-transparent photovoltaic module. Meanwhile, the electrical efficiency of PV

The comparison of Trombe wall systems with single glass, double glass

Sep 1, 2012 · In this paper, the energy performance comparison of single glass, double glass and a-Si semi-transparent PV module integrated on the Trombe wall façad

Optimized design and comparative analysis of double-glazed photovoltaic

Dec 15, 2024 · This study investigates the daylighting performance and energy efficiency optimization strategies of double-glazed photovoltaic windows (DS-STPV) in cold regions of

Glass/Glass Photovoltaic Module Reliability and

Aug 3, 2021 · Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with

How to distinguish single and double photovoltaic panels

The main difference between double-glass photovoltaic modules and single-sided glass solar panels lies in their construction and design, which can impact their durability, performance,

Single-glass versus double-glass: a deep dive into module

Oct 2, 2024 · There has been a noteable shift from the initial single-facial single-glass modules to bifacial double-glass modules. Double-glass modules, with their performance in the face of salt...

What is the difference between single crystal and double

The main difference between double-glass photovoltaic modules and single-sided glass solar panels lies in their construction and design,which can impact their durability,performance,and

Experimental repair technique for glass defects of glass-glass

Aug 1, 2023 · Solar photovoltaic (PV) energy is a crucial supply technology in the envisioned renewable energy system. With enormous amounts of PV modules being installed, some will

A Quantitative Comparison Between Double Glass Photovoltaic Modules

Jul 27, 2017 · We compared the output power of full-size, half-size, and quarter-size cells of a double glass transparent PV module quantitatively, finding cell-to-module values of 96.79%,

Photovoltaic glass: the perfect fusion between

Aug 18, 2025 · These photovoltaic modules use high-efficiency monocrystalline silicon cells (the cells are made of a single crystal of very high-purity silicon) to

Canadian Solar TOPCon Module Technical White Paper

Mar 15, 2023 · Since 2019, CSI Solar has been developing N-type TOPCon (Tunnel Oxide Passivated Contacts) technologies, and now launches a diversified TOPCon module portfolio

Glass/glass photovoltaic module reliability and degradation:

Aug 3, 2021 · Abstract Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with additional applications for

Bifacial single glass encapsulation of solar module – An

Jul 1, 2025 · Outdoor performance of PV modules encapsulated with two different approaches showed that annual power generation of single glass solar modules was higher than that of

Power generation ratio of double-glass photovoltaic

What is a bifacial photovoltaic (PV) specification? The specification entails measuring the current-voltage(I - V) characteristics of bifacial photovoltaic systems in natural or simulated sunshine.

Comparison of energy performance between PV double

Dec 12, 2023 · PV-DSF consists of an outside layer of semi-transparent a-Si PV (a-Si STPV) panel, an inner layer of glass sheet as well as an intermediate air ventilation cavity. The air

Double Glass vs Single Glass Solar Panel: Which

Feb 6, 2024 · Single glass panels are often slightly more efficient under ideal conditions due to their lighter weight, which allows for thinner layers between

6 FAQs about [Efficiency comparison between double-glass and single-glass photovoltaic modules]

What is the difference between single glass and double glass solar panels?

In conclusion, both single-glass and double-glass solar panels have their unique advantages. Single glass panels offer a tried-and-true solution with lower upfront costs and easier installation, while double glass panels provide enhanced durability, potential for higher energy production, and unique aesthetic possibilities.

What is double glass photovoltaic module?

Preface To further extend the s rvice life of photovoltaic modules, double glass photovoltaic module has cently been develop d and st died in the PV community. Double lass module contains two sheets of glass, whereby the back sheet is made of heat strengthened (semi-tempered) glass to substitute the traditional polymer backsheet.

Are double glass panels better than single glass?

This efficiency boost comes with a price, though. Single glass panels are often slightly more efficient under ideal conditions due to their lighter weight, which allows for thinner layers between the glass and cells. However, double glass panels hold the edge in durability, lasting longer and experiencing less performance degradation over time.

What is the difference between single glass and double glass?

During the day time when there is solar radiation, the single glass part has higher temperature values than the double glass and PV module parts due to the higher transmissivity character of the single glass. Fig. 12. The hourly experimental outlet air temperature changes of the PV module, double glass and single glass parts.

How do double glass solar panels work?

Construction: Double-glass modules consist of two layers of glass sandwiching the solar cells and other components. The glass layers are sealed together, encapsulating the solar cells and protecting them from environmental factors.

What is the difference between Raytech double glass solar modules?

Whereas for Raytech double-glass solar modules, with the increased strength brought by two layers of glass, a lot less deformation will happen in the solar cells, the possibility of microcracks formed on the solar cells will decrease significantly.

Update Information

- Nassau double-glass photovoltaic modules

- Black double-glass photovoltaic modules

- Double-glass photovoltaic module efficiency

- Latvian double-glass photovoltaic modules

- Double-glass photovoltaic modules in Rotterdam the Netherlands

- Naypyidaw double-glass photovoltaic modules

- High-efficiency double-glass solar photovoltaic modules

- Applicable scenarios for double-glass photovoltaic modules

- Photovoltaic modules double-glass double-sided

- Benefits of Bahrain double-glass photovoltaic curtain wall

- Photovoltaic double-glass components to build a sun room

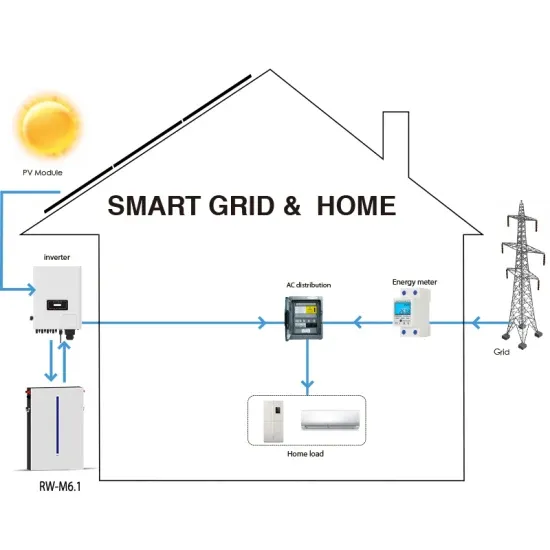

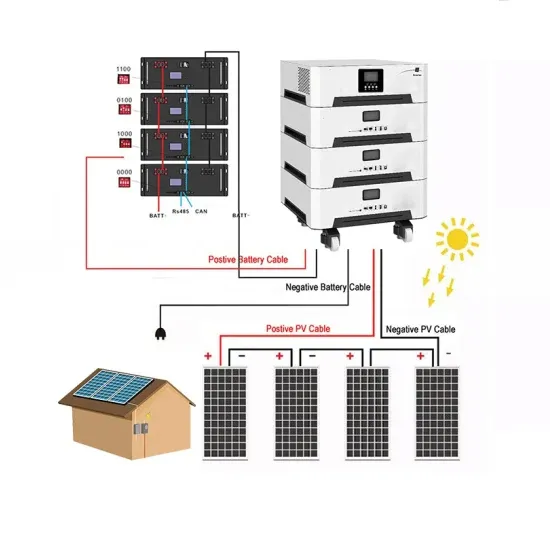

- What are the batteries for photovoltaic modules

- Are the glass of double-glass photovoltaic panels divided into upper and lower parts

Solar Storage Container Market Growth

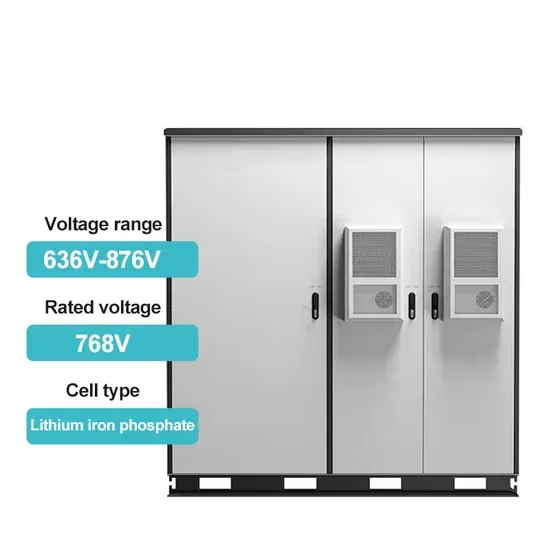

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.