Principle Cabinet Design EMC and grounding G574e Part 3

Mar 22, 2024 · The screen connection should be designed in such a way that grounding is possible. The best EMC suppression is achieved by a 360° grounding of the cable shield. The

Battery Cabinet Working Space Front Aisle Floor Loading

Minimum Size Conductor for Grounding the Battery Cabinet Battery Cabinet Breaker or Fuse Size Copper Wire Size Aluminum Wire Size Up to 200 Amps 6 AWG 4 AWG 201-300 Amps 4AWG

Server rack grounding | Information by Electrical

Mar 4, 2021 · Hi everyone, I need some advice in grounding service rack. if I am pulling a ground wire from panel that is approximately 90 feet away from the ground busbar, do I use #6 or #1

Server Rack Grounding | How To, Requirements,

Mar 24, 2022 · Server rack grounding is important. Learn if you should ground your server rack, get server rack grounding requirements, & discover how to

7 grounding, 8 remote battery cabinets/racks, 9 battery

GE Industrial Solutions SG Series UL LISTED BATTERY CABINETS User Manual • 7 grounding, 8 remote battery cabinets/racks, 9 battery wiring • GE Industrial Solutions Equipment

Standard Specification EPIC Series Battery Cabinet

Jan 23, 2025 · The EPIC Battery Cabinet will be an indoor or outdoor enclosure meeting either NEMA 1 or NEMA Type 3R rating requirements. For NEMA 3R, and when environmental

Battery Cabinet Working Space Front Aisle Floor Loading

Mounting the Battery Cabinet o Follow the recommended PPE requirements per the SDS for the battery to be used. (P/N 218710500) and #12 ground washers (three per side) (P/N

DC battery cabinet grounding requirements and standards

UBC80 Battery Cabinet Installation, Operation, Minimum Size Conductor for Grounding the Battery Cabinet Battery Cabinet Breaker or Fuse Size Copper Wire Size Aluminum Wire Size

Battery Cabinet Grounding System | HuiJue Group E-Site

When deploying battery cabinet grounding systems, have you considered how a single flawed connection might cascade into catastrophic failure? Industry reports show 43% of battery fires

TECHNICAL SPECIFICATION SECTION-GENERAL

Apr 18, 2023 · The equipment offered by the contractor shall at least conform to the requirements specified under relevant IS standard. In case of discrepancy between IS and other

Section 26 05 26 Grounding and Bonding for Electrical

Oct 28, 2024 · This specification is intended to be used in concert with related VA Standard Details. The A/E shall include details on the drawings, and edit details as necessary to comply

2018 Title Contents

Dec 20, 2022 · Which seismic code or standard is the best fit? The best seismic code or standard may be subjective and depending on the industry, options might be limited. There are many

Installation Planning Guide for 500kVA UPS

May 2, 2022 · Battery Input (480VDC Nominal) Battery Capacity Required for Full Load Output Suggested External Overcurrent Protection Three (3) Cabinets: DC Cable Size per Cabinet***

Site Considerations for Equipment Installation,

May 31, 2024 · Grounding Equipment Ground metal enclosures and exposed metal parts of electrical instruments in accordance with relevant safety standards. For the USA, refer to

SPECIFICATION STANDARD GROUNDING AND

Jul 18, 2022 · The grounding and bonding system refers to all electrodes required by NEC, as well as including made, supplementary, information technology and telecommunications system

Grounds for Grounding: A Handbook from Circuits to

Dec 23, 2022 · Grounding procedures used in the design and assembly of electrical and electronic systems will protect personnel and circuits from hazardous currents and damaging

Why Should Battery Racks Be Grounded? Safety and

Jun 15, 2025 · Battery racks should be grounded to prevent electrical hazards, reduce fire risks, and ensure compliance with safety standards like NEC Article 480 and NFPA 70. Grounding

Enclosure 6160-b160 Install Guidelines 4.4 [poeglevn6e2l]

Added MW systems integration, equipment (device chassis) grounding standards, HCS cable management update, Conduit plan further details Added HCS grounding standards link.

How to Properly Ground a Car Battery

Apr 4, 2025 · To properly ground a car battery, you need to securely connect the negative terminal to a clean, unpainted metal surface on the vehicle''s chassis. Many car owners

R16AN0049EU: Importance of Grounding in Battery

Jul 2, 2024 · Grounding considerations for Battery Management Systems (BMS) in battery-operated environments are crucial for ensuring safety, functionality, and accurate battery

Principle Cabinet Design EMC and grounding G574e Part 3

Mar 22, 2024 · The PE busbar has to be fixed to the cabinet frame by screws to provide grounding The cross section of the grounding busbar or cable has to be at least half of the

USER MANUAL BATTERY CABINET

Jul 28, 2025 · e installing any batteries. Attach an Equipment Grounding Conductor (EGC) from the cabinet''s grounding fastener to the Equip Protection of the cabinet. Refer to an NEC

6 FAQs about [Battery cabinet grounding wire standard specification]

What standards are used in a battery room?

Common standards in the battery room include those from American Society of Testing Materials (ASTM) and Institute of Electrical and Electronic Engineers (IEEE). Model codes are standards developed by committees with the intent to be adopted by states and local jurisdictions.

Why is grounding important in battery management systems (BMS)?

Grounding in Battery Management Systems (BMS) is crucial for ensuring voltage and current measurement accuracy. Accurate voltage measurements depend on a stable ground reference. If the BMS ground is improperly connected or affected by noise, voltage readings can become distorted.

Do I need a grounding cable if my cabinet is painted?

If the cabinet is painted, all components and installation plates should be grounded via a cable to the grounding busbar. Body grounding does not replace a protective earth connection. PE conductors are always required from the PE terminal of the device to the PE busbar if there is body grounding or not.

How do I equalize the grounding of a battery pack?

Additionally, connecting the isolated battery pack ground to earth ground before making other connections between the pack and the test system or external communications interface can help equalize grounds. 11. Connection Scenarios The following describes BMS grounding issues in different connection scenarios.

How should a power cable be connected to a grounding busbar?

Run signal and data cables between different cubicles close to the grounding busbar. Keep power cables separate from other cables. There should be at least 50cm of distance between power cables and signal/control cables. There should not be any long parallel runs.

How do you ground a cable with a screen?

Cables equipped with a screen must be connected to ground. The screen connection should be designed in such a way that grounding is possible. The best EMC suppression is achieved by a 360° grounding of the cable shield. The grounding distance and impedance should be as short and low as possible. See the pictures for different alternatives.

Update Information

- How to connect the ground wire in the battery cabinet

- Energy storage battery cabinet fire protection acceptance specification

- Battery Cabinet Photovoltaic Price

- Battery cabinet parts

- Sao Tome and Principe Outdoor Communication Battery Cabinet New Energy

- New energy endurance plus battery cabinet

- Normal price of energy storage cabinet battery

- Which site cabinet is used for the battery cabinet

- Energy storage battery cabinet line base station

- How much is the preheating current of the battery cabinet

- Abuja outdoor communication battery cabinet

- Battery cabinet replacement cost

- Battery cabinet process step settings

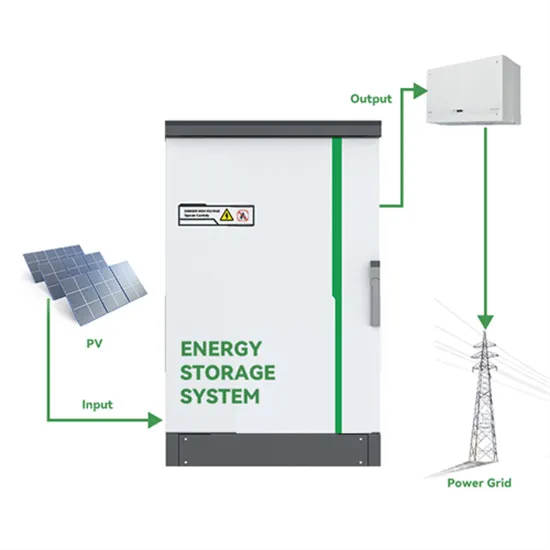

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.