Lithium battery module strapping, PET tape or

May 16, 2024 · Lithium battery module strapping, PET tape or steel tape?Steel tape Steel tape is a narrow strip packaging material with high tensile strength

Lithium Battery Module Pack Steel Band

Jul 19, 2025 · Through modular design (battery cell → module → battery box → system), standardized modules fixed with steel strips can be independently disassembled and replaced,

Everything You Need to Know About Sizing Nickel Strips for

May 8, 2025 · Learn how to size nickel strips for batteries, including thickness, width, and material selection, to ensure safe, efficient, and durable battery pack performance.

HARFINGTON 50pcs Pure Nickel Strip 0.1 x 4 x 100mm

Nov 23, 2024 · Pure nickel strips and tin wire are easy to weld, after making the battery pack, you only need to connect the wires and then weld them with tin wire, the nickel strip can be firmly

1M Nickel Strip, Nickel-Plated Steel Strip, Plated Steel Strip

Apr 25, 2023 · 【Product Features】: Mainly used as battery connection sheet. Smooth surface, no scratch or burrs, easy to weld. It works with battery spot welder to connect batteries.

Nickel Strip – 5mm x 0.12mm – For Battery Pack – 1 Meter –

Buy Nickel Strip - 5mm x 0.12mm - For Battery Pack - 1 Meter - Plated online from KTRON India. Its a nickel plated strip used in spot welding a battery pack

NIONSUPPLY 100pcs 2P H type T type Nickel Plated Steel Strips

Jun 30, 2022 · 100pcs 2P H type T type Nickel Plated Steel Strips Sheet Soldering Tabs for DIY 18650 Lithium Battery Pack, Battery Connector Tab Battery Cell Spot Welding Welder (T type)

Why Nickel Strips Are Ideal for Battery Packs

Apr 24, 2024 · Nickel strips are perfect for battery packs because they can handle high heat, resist rust, and are strong yet flexible. Plus, they''re cost-effective,

Are Nickel Strips the Right Material for Your Battery Pack?

Aug 17, 2025 · Learn why nickel strips are preferred for battery packs, offering excellent conductivity, corrosion resistance, and reliable performance.

AXY 18650 Nickel Strip H-Type Thickness 0.12 Width 27mm

18650 Nickel strip H-type Thickness 0.12 width 27mm Nickel plated 2P roll for lithium ion battery pack making. By using this H-type Nickel strip you can connect the cells by spot welding.

Nickel Plated Steel Strip For 2S2P 2S4P 2S6P 18650 Battery Pack Welding

Nickel Plated Steel Strip for 2S2P 2S4P 2S6P 18650 Battery Pack. Welding. Product Description. Made of high quality material, solid, durable, with good gloss, low resistance, corrosion

Is it bad to use nickel plated steel strips to build a battery pack

May 15, 2020 · So I got ripped off from aliexpress when I bought a roll of 0.15x8 mm and 0.15x5mm nickel strips. They are not pure nickel as I did a salt water test and they rusted. I

HARFINGTON Nickel Strip 0.15mm x 5mm (32.8ft / Roll)

Nov 11, 2024 · HARFINGTON Nickel Strip 0.15mm x 5mm (32.8ft / Roll) Nickel Plated Steel Strips for Lithium Battery Packs Car Nickel Tap for Cell Battery Pack Spot Welding and Soldering,

Nickel Plated Steel Strip For 2S2P 2S4P 2S6P 18650 Battery Pack Welding

Tmax is a professional Nickel Plated Steel Strip for 2S2P 2S4P 2S6P 18650 Battery Pack Welding,Nickel Strip Roll supplier from China,we have gained more than 20 years mature

How To Differ Between Pure Nickel Strip Battery Tabs Vs. Steel

When putting together an ebike battery pack, you want to make sure you''re using pure nickel strips and not nickel coated steel trips. Conductive metal strips are spot welded between all

6 FAQs about [Pack battery pack steel strip]

How to choose a nickel strip for a lithium battery?

The width and material of the nickel strip should be selected according to the current of the lithium battery pack. In terms of material, there are two commonly used nickel strips: pure nickel strips and nickel plated steel. What is the difference between their performance and actual use?

How thick is a nickel strip on a battery pack?

The nickel strip on the battery packs I have is approx 0.3mm thick and is nickel-coated steel strip. It is welded 4 times per cell per side (2 weld operations, 4 indents from the spot welding pins). The diameter of the indents is approximately 1mm or perhaps 0.8mm. My current approach: The pliers look like these:

What is nickel strip?

Nickel strip is a material often used in series and parallels lithium battery packs. The width and material of the nickel strip should be selected according to the current of the lithium battery pack. In terms of material, there are two commonly used nickel strips: pure nickel strips and nickel plated steel.

Is nickel strip better than nickel plated steel?

Pure nickel strip is better than nickel plated steel. Pure nickel strip has strong corrosion resistance. In the salt spray test, the corrosion resistance of pure nickel strips is obviously better than that of nickel plated steel.

How much current can a nickel strip withstand?

For nickel-plated steel, its calculation formula is usually calculated according to 7A/mm², that is to say, the maximum continuous overcurrent of nickel-plated steel with a thickness of 0.15mm*7mm is 7*0.15*7=7.35A. It can be seen that the current that a pure nickel strip can withstand is about 1.5 times that of nickel plated steel.

What are the advantages of pure nickel strips?

This is also one of the favored advantages of pure nickel strips. During the packing process, the connection between nickel strips and cells are all resistance spot welding methods, like cylindrical cells, 18650/26650/32700, so the greater the internal resistance of the nickel strip, the more the welding effect is better.

Update Information

- Long strip lithium battery pack

- Spanish 72v lithium battery pack

- Nassau st lithium battery pack

- Lithium battery pack safety

- Saint Lucia Power Lithium Battery Pack Customization

- North Korea pack lithium battery project

- 48V10ah lithium battery pack discharges quickly

- Tuvalu energy storage lithium battery pack customization

- Lithium battery pack has a string of small capacity

- 28v lithium battery pack usage

- Energy storage cabinet battery cluster and pack

- How long does it take to customize a lithium battery pack

- Helsinki lithium battery pack series connection

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

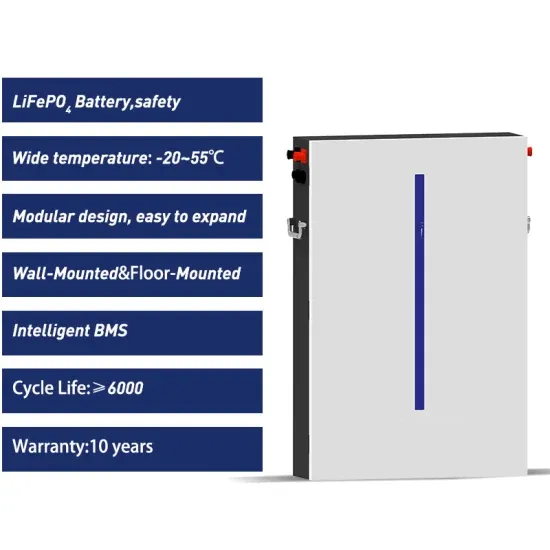

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.