Enhancing lithium-ion battery pack safety: Mitigating

Jul 1, 2024 · For the battery pack protected using the OP44/EG CPCM represented in Fig. 10, the triggered battery and the three nearby batteries in the pack exhibited TR one after another,

Design and manufacture of thermoplastic carbon

Jun 1, 2022 · The CPB is positioned slightly in front of the battery pack to protect the battery first in the event of a collision with large ground obstacles. For the mounting, the brackets were

Tape Solutions for EV Battery Pack Protection

Dec 5, 2023 · Tape Solutions for EV Battery Pack Protection Saint-Gobain® Norseal® Gasketing Foams and ThermaCool® Thermal Interface Products ofer a wide range of solutions for

Battery Pack and Underbody: Integration in the

Apr 23, 2023 · This solution is also one of the most interesting from the point of view of the battery pack protection in case of a lateral impact and for easy

Electric Vehicle Battery Packs

Jan 10, 2023 · With its high-energy absorption capabilities, cost efective NORYLTM GTXTM resin battery protection solution can help protect the battery during impact. The single-piece,

Electric Vehicle Battery Packs

Jan 10, 2023 · For larger pack enclosures where modulus is more critical, glass fiber filled NORYLTM NHP5054 resin is positioned ofering greater stifness and a UL94 V0 flame rating at

Battery Pack Protection and Management | Ansys Courses

This lesson covers the integral aspects of battery pack protection and management. It delves into the undesirable events that necessitate the use of protection schemes, such as excessive

Battery Pack Sealing and Protection

Apr 22, 2024 · specifically designed for electric vehicles. The cooling plate is a single large plate that is fixed to the top surface of the cells. The coolant connections are both at the front of the

Battery Pack Design Considerations for Performance and

1 day ago · Question: Do all battery packs need a BMS to control the charge and discharging? Answer: The BMS is mainly for lithium batteries, but we have some nickel battery designs, like

Crashworthiness of Protected Battery Pack

A new protection method was proposed to improve the crashworthiness of cylindrical battery packs. The crashworthiness of unprotected battery pack, resin protecting battery pack and

Battery protection units (BPU) | Infineon Technologies

A battery protection unit (BPU) prevents possible damage to the battery cells and the failure of the battery, enhancing the useful operating life of lithium-ion batteries by protecting the battery

Battery Coatings Enhancing EV Performance and Safety

Coatings are applied throughout an EV battery pack, from fire protection materials on the lid, anti-corrosion protection inside and out, on cooling plates and pipes, on busbars and in cells.

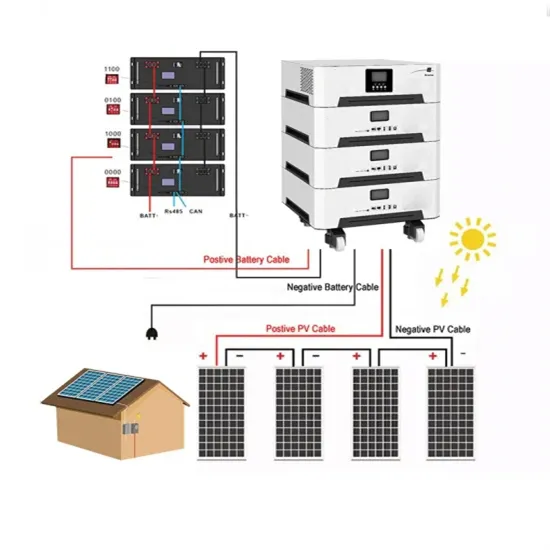

Lithium Battery Pack Protection and Control

Safety and ageing concerns in Lithium battery applications highlight the critical need for advanced protection and control solutions in the market. Adoption of electric vehicles, both in the

Space-efficient protection for cylindrical batteries embedded

Apr 1, 2024 · The above literatures indicated that the mechanical behaviors and the failure mode of packed batteries are more complex than that of individual cells, which brings challenges for

6 FAQs about [Pack protect battery]

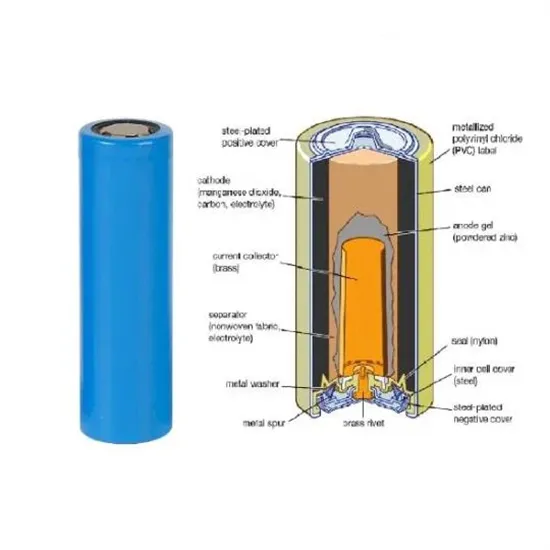

What is a battery pack?

A battery pack is a group of cells packaged into one unit, typically to achieve higher power and/or current loads. In most cases, batteries are first assembled into ‘modules’ with a fixed number of cells, and then the modules are assembled into packs.

How can the safety of a battery pack be improved?

The NavTruss sandwich structure can improve the safety of a battery pack, but not as effectively as the BRAS design. The other two designs, the double-layered plate using two different aluminums and the enhanced housing box, are not as effective as the baseline design.

What are the requirements for a battery pack enclosure?

Labelling – a battery pack needs labels that define what it is and warnings about it’s safe handling and use. The requirements are market and pack type dependent. A battery pack enclosure can be in many forms depending on the application.

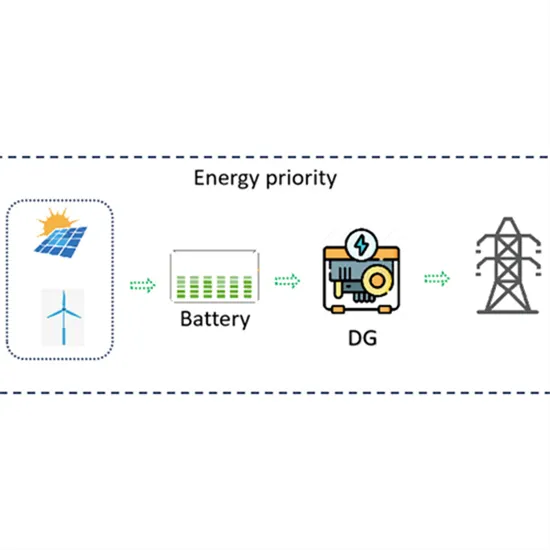

How can a battery management system ensure safety and security?

The most viable way to enforce the safety and security of battery packs is via integration with the battery management system. BMS can safeguard the battery pack from a wide range of potential threats such as overcurrent, instantaneous ignition, temperature, and voltage fluctuations.

Are lithium-ion batteries safe?

The lithium-ion battery is one of the most vulnerable battery types in the sense that any voltage, current, temperature, or short circuit fluctuation can lead to a catastrophe. The most viable way to enforce the safety and security of battery packs is via integration with the battery management system.

What are the dangers of a battery pack?

The hardest and most hidden threat of the battery pack is fire. No manufacturer or EV driver would ever think about their battery energy storage systems catching fire. This type of catastrophe may sometimes arise from sparking or burning due to the manufacturing defects such as internal short circuits.

Update Information

- Spanish 72v lithium battery pack

- Tashkent 72v75ah lithium battery pack

- Lithium battery pack large company

- Long strip lithium battery pack

- Lithium battery pack safety

- Saint Lucia Power Lithium Battery Pack Customization

- Energy storage cabinet battery cluster and pack

- 48V10ah lithium battery pack discharges quickly

- 11V lithium battery pack

- Nanya lithium battery pack

- Helsinki lithium battery pack series connection

- Lithium battery pack has tolerance

- Sales of lithium battery pack manufacturers

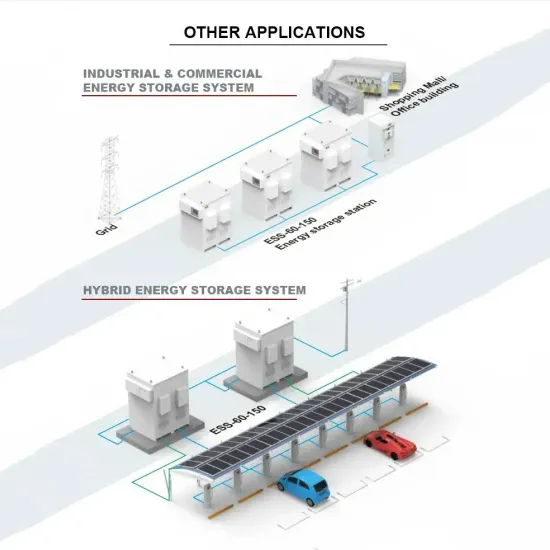

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.