Lithium battery pack series and parallel connection

Lithium Battery Instructional Wiring Diagram . Lithium Battery Wiring Instructions. All battery interconnects, busbar and device connections to resist vibration by using nylon insert lock

Series vs Parallel: Understanding battery connections in one

Sep 21, 2024 · Parallel connections, on the other hand, increase the battery''s capacity, making them perfect for applications requiring longer runtimes or greater energy storage. In most

BATTERY-BOX PREMIUM LVS LITE

Aug 16, 2021 · The BYD Battery-Box Premium LVS Lite is a lithium iron phosphate (LFP) battery pack for use with an external inverter. A single Battery-Box Premium LVS Lite contains

Battery in Series vs Parallel: The Complete Power

Mar 23, 2025 · Discover the key differences between batteries in series vs parallel configurations. Learn which setup maximizes voltage, capacity, and safety for

Strings, Parallel Cells, and Parallel Strings

Feb 15, 2016 · Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost and simplest. However,

Lithium-ion battery pack in series or parallel

Mar 19, 2025 · The goal is to build a 200 V Lithium-ion battery pack using 21700 cells. I am trying to make a design decision on lithium-ion battery pack architecture for an electric vehicle and it

3. Battery bank wiring

Aug 30, 2024 · The maximum is at around 3 (or 4) paralleled strings. The reason for this is that with a large battery bank like this, it becomes tricky to create a balanced battery bank. In a

Understanding Battery Pack Configurations: Series vs. Parallel

Feb 17, 2025 · Many battery packs combine series and parallel connections to get the best of both worlds—higher voltage and longer battery life. If you connect four 3.6V Li-ion cells (each

Can I parallel multiple Lithium Battery Packs?

May 27, 2025 · The short answer is yes, you can parallel multiple lithium battery packs. However, there are several factors you need to consider to ensure a safe and efficient operation. One of

Battery configurations (series and parallel) and

Jun 26, 2023 · The other lithium-based battery has a voltage between 3.0 V and 3.9 V. Li-phosphate is 3.2 V, Li-titanate is 2.4 V. Li-manganese, and other

What is lithium battery series and parallel connection, series

6 days ago · In a lithium battery pack, several lithium batteries are connected in series to get the required working voltage. If you need higher capacity and higher current, you should connect

How Series and Parallel Cell Arrangements

Mar 3, 2024 · The configuration of lithium-ion battery packs, particularly the total number of cells connected in series and parallel, has a great impact on the

Strings, Parallel Cells, and Parallel Strings

Feb 15, 2016 · Strings, Parallel Cells, and Parallel Strings Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

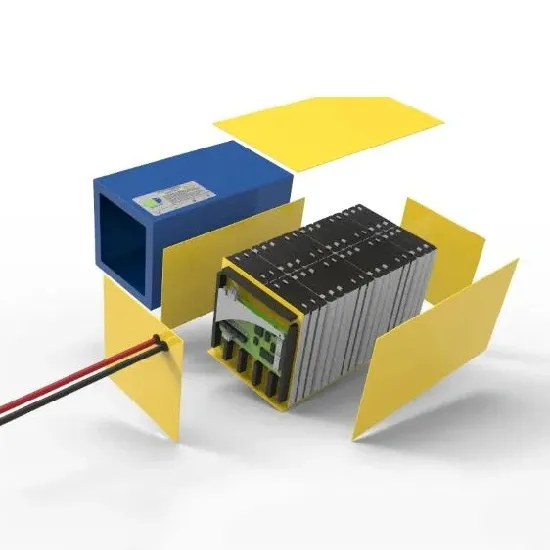

Feb 15, 2025 · Designing a lithium-ion battery pack is a complex and multifaceted process that requires a deep understanding of the components, configurations, and safety considerations

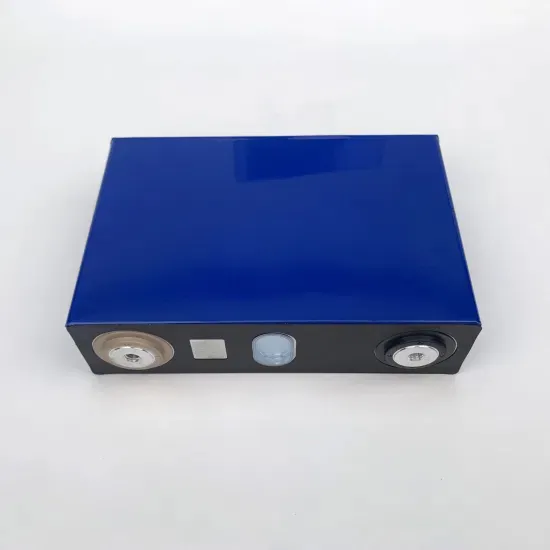

Battery cell, Battery Module or Pack. What''s the

Jun 20, 2023 · A lithium battery module is composed of several to hundreds of battery cells connected in parallel and series. In addition to the structural

How to Build a LiFePO4 Battery Pack (Step-by-Step, Pro Tips)

3 days ago · Complete step-by-step guide to building a LiFePO4 battery pack. Learn series vs parallel, BMS installation, specs, common mistakes, and maintenance tips.

Amazon : 18650 Parallel Battery Holder

18650 Battery Case Holder, 5 Pack 3 Slots x 3.7V DIY Battery Storage Box, in Parallel Black Plastic Batteries Case with Pin for 3 x 18650 124 $999 ($2.00/Count) FREE delivery Wed, Apr

Performance reliability analysis and optimization of lithium

Apr 1, 2021 · A response surface method with the Box-Behnken design method is applied to reduce the number of simulation trials. Then, the redundancy scheme and two layouts of a

Series-Parallel Battery Configurations Guide 2025

Mar 1, 2025 · In 2024 stress tests, our parallel-connected 24V LiFePO4 batteries demonstrated: For projects requiring rapid deployment, our pre-configured 12V lithium battery packs support

Management of imbalances in parallel-connected lithium-ion battery

Aug 1, 2019 · Uneven electrical current distribution in a parallel-connected lithium-ion battery pack can result in different degradation rates and overcurrent issues in the cells. Understanding the

Explosion-proof lithium-ion battery pack

Jun 15, 2022 · The catastrophic consequences of cascading thermal runaway events on lithium-ion battery (LIB) packs have been well recognised and studied. In undergr

Series vs Parallel Battery Wiring: The Ultimate 2025 Guide

Apr 18, 2025 · Learn the key differences between series and parallel battery wiring. Discover how to optimize voltage, capacity, and performance for your energy needs in 2025.

1000A UltraSafe Jump Starter – 12V Lithium Battery Booster Pack

1 day ago · 1000A UltraSafe Jump Starter – 12V Lithium Battery Booster Pack, Portable Jump Box, Power Bank & Jumper Cables - for 6.0L Gas and 3.0L Diesel Engines.

[2508.14454] Reformulating Parallel-Connected Lithium-Ion Battery Pack

6 days ago · This work presents analytical solutions for the current distribution in lithium-ion battery packs composed of cells connected in parallel, explicitly accounting for the presence of

Batteries in Parallel vs Series, All You Need to

Jan 20, 2024 · Why Does Battery Type Matter in Wiring Configuration? Lithium (LiFePO4) and lead-acid batteries behave differently. LiFePO4 tolerates series

6 FAQs about [Lithium battery pack parallel box]

What happens if a lithium-ion battery is connected parallel?

Uneven electrical current distribution in a parallel-connected lithium-ion battery pack can result in different degradation rates and overcurrent issues in the cells. Understanding the electrical current dynamics can enhance configuration design and battery management of parallel connections.

Should a battery pack be paralleled?

Paralleling strings together greatly increases the complexity of managing the battery pack and should be avoided unless there is a specific reason to use this configuration. In this setup, each string must essentially be treated as its own battery pack for a variety of reasons. In a below example, 2 strings of 8 cells each are placed in parallel.

Can a lithium ion battery pack have multiple strings?

Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost and simplest. However, sometimes it may be necessary to use multiple strings of cells. Here are a few reasons that parallel strings may be necessary:

Why do I need to add batteries in parallel?

If your load requires more current than a single battery can provide, but the voltage of the battery is what the load needs, then you need to add batteries in parallel to increase amperage. Wiring batteries in parallel is an extremely easy way to double, triple, or otherwise increase the capacity of a lithium battery.

Can You charge a lithium ion battery in parallel?

Charging cells in parallel is not much different than charging them on their own. For example, if you have a single lithium-ion cell that has a max charge voltage of 4.2 volts and a max charge current of 2 amps, you can use those same settings to charge a battery that has 3, 20, or even 100 of those battery cells in parallel.

Should lithium ion batteries be wired in series or parallel?

When wiring lithium-ion batteries in series, the voltage is changed which can damage equipment if not performed with caution and great understanding. In contrast, wiring lithium batteries in parallel keeps the voltage the same while simply giving the batteries the ability to supply that same voltage level for longer.

Update Information

- 8 parallel 13 series lithium battery pack

- 48V lithium battery pack in parallel

- Quick assembly of lithium battery pack

- 24v150 lithium battery pack

- Austria ups power lithium battery pack

- Large capacity 26650 lithium battery pack

- Ouagadougou liquid-cooled energy storage cabinet system lithium battery pack

- Maldives ultra-large capacity lithium battery pack

- Unicycle lithium battery pack

- Lithium battery pack manufacturer in Nairobi

- 20v lithium battery pack to 12v

- 72V 6Ah Lithium Battery Pack

- Lesotho Power Lithium Battery Pack

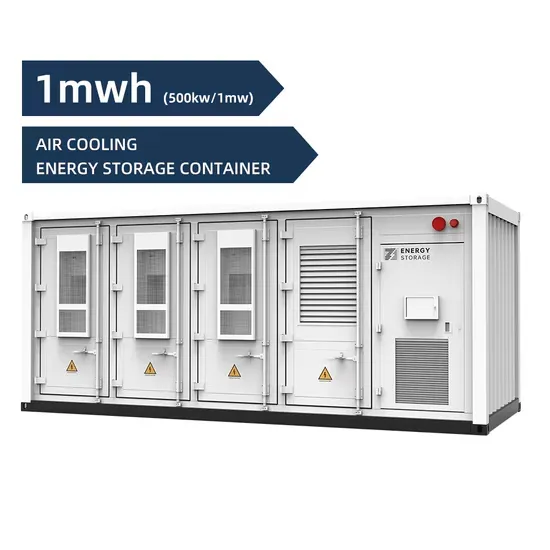

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.