What is the air duct design of energy storage container

Liquid air energy storage, in particular, has garnered interest because of its high energy density, Consequently, there is an urgent need to develop the design optimization of liquid air-based

Energy storage cabinet air cooling duct structure

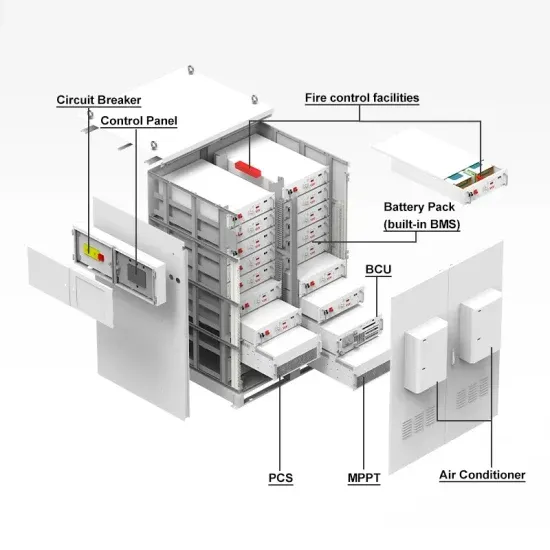

The 115kWh air cooling energy storage system cabinet adopts an "All-In-One" design concept, with ultra-high integration that combines energy storage batteries, BMS (Battery

某型集装箱储能电池组冷却风道设计及优化

Jun 1, 2020 · 本工作以某型集装箱储能系统为研究对象,针对集装箱内部左右两侧的储能电池组提出了"主风道+立管"形式的均匀送风方案;基于CFD技术对其

Energy storage cabinet air cooling duct structure

Energy storage cabinet air cooling duct structure Does airflow organization affect heat dissipation behavior of container energy storage system? In this paper,the heat dissipation behavior of the

How Should Energy Storage Containers Be Designed?

Mar 7, 2025 · 1) Energy storage containers with high structural and functional similarity should be combined. 2) When connecting corresponding components, the number of connections should

Energy storage container battery rack air duct

Airflow reorganization and thermal management in a large-space battery The present paper numerically investigates the air-cooling thermal management in a large space energy storage

300KWh-2000KWh Containerized Battery Energy Storage

Huijue''s container energy storage is composed of 10/20/40-foot prefabricated cabins. It is a container that meets megawatt-level power output requirements and integrates energy storage

Cooling air duct design for container energy storage battery

The main point of the design of forced air-cooling technology is to control the air duct to change the wind speed: due to the different energy density and capacity of the batteries in the energy

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · This study analyses the thermal performance and optimizes the thermal management system of a 1540 kWh containerized energy storage battery system using CFD

Air duct of energy storage container and energy storage container

A container and air duct technology, applied to structural parts, electrical components, electrochemical generators, etc., can solve the problems of reduced system life, large

Understanding the Air Duct Design in Air-Cooled Energy Storage

Jun 11, 2025 · Air duct design in air-cooled energy storage systems (ESS) refers to the engineering layout of internal ventilation pathways that guide airflow for optimal thermal

Energy storage container and heat dissipation system and

A technology for cooling air ducts and containers, which is applied in the fields of cooling air ducts, energy storage containers and their cooling systems, can solve the problems of poor

Energy Storage Containers: How Battery Rack Air Duct

The Hidden Challenge in Modern Energy Storage Systems You know what''s surprising? Over 60% of battery storage failures stem from thermal issues rather than chemical degradation. As

Design and optimization of the cooling duct system for the

Nov 5, 2020 · Semantic Scholar extracted view of "Design and optimization of the cooling duct system for the battery pack of a certain container energy storage" by Y. Zou et al.

how big is the air duct design of the energy storage container

Design and optimization of the cooling duct system for the battery pack of a certain container energy storage A personalized uniform air supply scheme in the form of "main duct + riser" is

HOW BIG IS THE AIR DUCT DESIGN OF THE ENERGY

Here''s how to install air ducts Energy Storage Container integrated design for easy delivery; Control the cooling and heating system of the air conditioner through thermal management

Container energy storage air duct design

About Container energy storage air duct design With the rapid advancement in the solar energy sector, the demand for efficient energy storage systems has skyrocketed. Our featured grid

Airflow reorganization and thermal management in a

Nov 1, 2024 · The present paper numerically investigates the air-cooling thermal management in a large space energy storage container in which packs of high-power density batteries are

Air duct device and energy storage container

The utility model provides an air duct device and an energy storage container, and relates to the technical field of energy storage air ducts. The pipeline is equipped with air intake and two at

Energy storage container battery rack air duct requirements

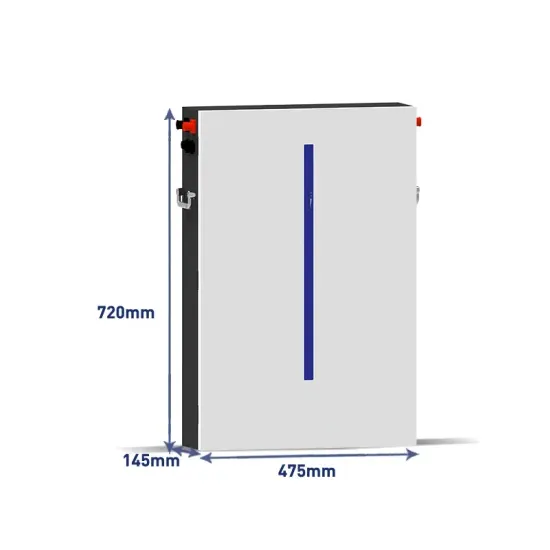

A thermal management system for an energy storage battery container based on cold air The energy storage system (ESS) studied in this paper is a 1200 mm × 1780 mm × 950 mm

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · The internal resistance remains unchanged during battery discharge [38, 39]; (3) The walls of the container do not transfer energy and matter to the outside world, and are

Optimization of guide plates and orifice plates on thermal

Sep 15, 2024 · In order to solve the problem of uneven air supply in traditional duct, the present study proposes a composite duct structure with optimized L-type guide plates and orifice

6 FAQs about [Energy storage container cooling duct]

What is a containerized energy storage battery system?

The containerized energy storage battery system comprises a container and air conditioning units. Within the container, there are two battery compartments and one control cabinet. Each battery compartment contains 2 clusters of battery racks, with each cluster consisting of 3 rows of battery racks.

Are air cooling systems good for energy storage?

Air cooling systems, favoured for their low cost, simplicity, and space efficiency, are widely utilized in practical energy storage applications . However, they exhibit lower efficiency at high discharge rates and temperatures, resulting in uneven battery temperatures [16, 17].

Can CFD simulation be used in containerized energy storage battery system?

Therefore, we analyzed the airflow organization and battery surface temperature distribution of a 1540 kWh containerized energy storage battery system using CFD simulation technology. Initially, we validated the feasibility of the simulation method by comparing experimental results with numerical ones.

Does air-cooling improve battery thermal management system?

The air-cooling system is of great significance in the battery thermal management system because of its simple structure and low cost. This study analyses the thermal performance and optimizes the thermal management system of a 1540 kWh containerized energy storage battery system using CFD techniques.

What is a containerized storage battery compartment?

The containerized storage battery compartment is separated by a bulkhead to form two small battery compartments with a completely symmetrical arrangement. The air-cooling principle inside the two battery compartments is exactly the same.

Where is the air supply duct located?

The air supply ducts are positioned directly above the battery racks, with six identically sized air conditioning vents along the duct sidewalls, opposite the partition. The control cabinet is situated on the left side of the battery compartments, while the air conditioning units are installed on the right side of the container. Fig. 1.

Update Information

- Suriname Liquid Cooling Energy Storage Container Company

- Djibouti Energy Storage Liquid Cooling Container Factory Operation

- Havana Liquid Cooling Energy Storage Container Selling Price

- Liquid Cooling Energy Storage Container Price in Cebu Philippines

- Austrian Liquid Cooling Energy Storage Container Company

- Bamako Liquid Cooling Energy Storage Container Manufacturer

- Liquid Cooling Energy Storage Container Base Station

- 6MW energy storage battery container liquid cooling system

- Lebanon Energy Storage Cabinet Container

- Price of container energy storage lithium battery

- How big is the energy storage container factory

- South African container energy storage raw materials manufacturer

- Cameroon Energy Storage Cabinet Container Company

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.